PautaInternas

PautaInternas

buscador

buscador

Strategic Deployment: Life first

Strategic Deployment: Life first

Strategic Deployment: Life first

Apr 9, 2025

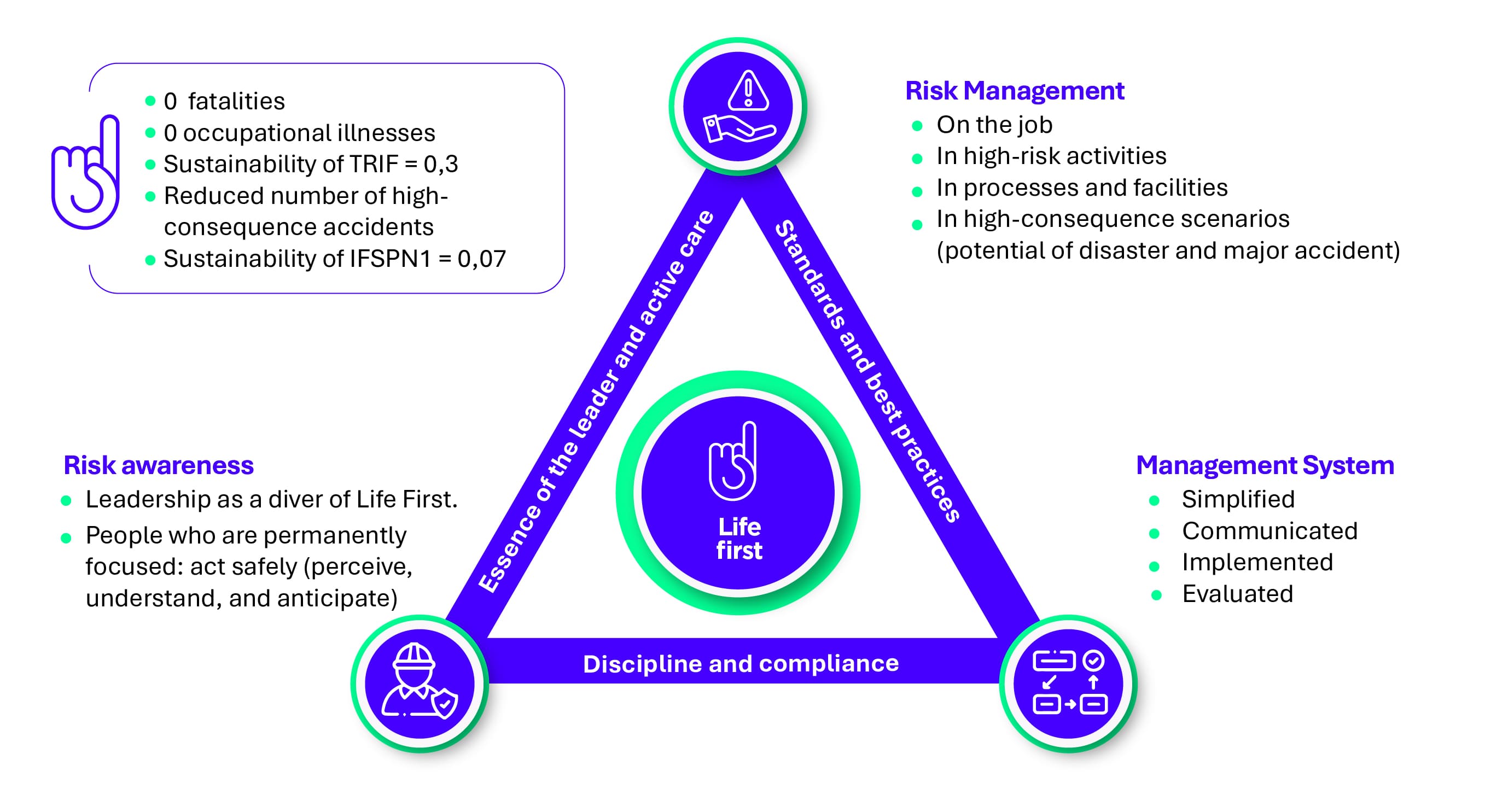

Life first is one of the cultural principles of the Ecopetrol Group that is fully integrated with other principles: always ethical, passionate about excellence, we listen with respect and speak with clarity, we make the impossible possible, and we are a single team

Image 1. Life First

The cultural principle leverages the behavior of the employees who help us achieve our goals.

- Ecopetrol leaders are committed to Life First, in the day-to-day activity, when they:

- Encourage well-being and self-care of the members of the team they lead.

- Lead their team by example, complying with HSE regulations.

- Lead their team by prioritizing life and respect for people above results.

Ecopetrol goals, for which we work every day, are:

- Protect the life of the people and the environment through proactive management of risks, with the highest safety and health standards at work.

- Perform operations under tolerable levels of risk in occupational health, safety, and process safety sustainably over time.

- Promote, maintain, and improve the physical, mental, and social health of workers and thus contribute to their quality of life.

To achieve these objectives, the organization has defined a series of management programs that translate into continuous improvement in employee health and safety as it focuses efforts and resources in an organized and systematic manner. Said programs are reviewed annually, allowing for periodical update, incorporating necessary changes according to the nature of our operations, as well as the needs and expectations of our clients and other stakeholders.

Strategic focus on occupational health and safety.

The strategy leverages on three fundamental pillars:

Image 2. Strategic focus on occupational health and safety

Risk Management

Risk management is the fundamental pillar for addressing hazards associated with safety and health at work. Ecopetrol abides by the provisions of the ISO 31000:2018 standard and applies references for the management of barriers and control measures.

Risk awareness

All employees must be able to perceive hazards and risks of the areas and processes where they perform their activities:

- Understand them.

- Reflect about them.

- Implement effective measures for their control.

- In general, they tend to take care of themselves and of others.

- Employees must achieve and maintain a sense of vulnerability to risk.

All officials must have behaviors and competencies related to safety and health at work that generate trust, solidarity, and generative dialogue. Through collective leadership, we must all encourage protection of life as per the highest health and safety standards.

Management System

Commitment of ECP to safety, processes, and health at work.

Ecopetrol S.A. has implemented an HSE Management System, which aims to be efficient and simple to understand and apply at all levels of the organization, establishing the necessary elements for the company to adequately manage risks, thus protecting life and promoting care for the environment. The basic mandatory requisites of the HSE Management System are based on international standards ISO 14001: 2015 and ISO 45001:2018 and certified to ensure compliance with national legislation. This commitment is further evidenced within the Comprehensive Policy of Ecopetrol S.A, through the principles of Commitment to Life and Operational Excellence.

The review of compliance with the Comprehensive Policy of Ecopetrol S.A. is conducted through the HSE Committee of the Board of Directors in accordance with the provisions of the internal regulations of said committee, in article 10:

* Numeral 8: Evaluate and provide recommendations for decision and consideration of the Board of Directors related to actions that affect the HSE performance of the Ecopetrol Group companies.

* Numeral 9. Examine and follow up the HSE strategy defined for the Ecopetrol Group.

* Numeral 10: Review and monitor the HSE management model of Ecopetrol and the Ecopetrol Group.

C E JD Regulations: https://www.ecopetrol.com.co/wps/wcm/connect/185869e5-8d42-44e7-9ab6-1142693d8bbe/201019+GOC-R-018+Reglamento+del+Comit%C3%A9+HSE.pdf?MOD=AJPERES&attachment=false&id=1605286512921

The HSE Management System is governed by the Vice Presidency of Territorial Transformation and HSE of Ecopetrol S.A., and it covers oil and gas exploration and production processes, refined products and petrochemicals, hydrocarbons marketing, and administrative and/or business support processes. Likewise, the HSE Management System applies to employees and contractors involved in all company processes and is intended to promote leadership and commitment by establishing objectives, implementing best practices, and carrying out monitoring and improvement, where improvement opportunities are identified and prioritized, and action plans are implemented to achieve the expected outcome, ensuring continuous improvement of the System, with indicators such as the TRIF (Recordable Injury Rates), an indicator in which we are an international reference.

Through the HSE Management System, processes are established, implemented, and maintained for consultation and participation of workers representatives at all levels and areas of company operations. Additionally, HSE requirements and obligations (Health, Safety, Process Safety and Environment) are established in the various phases of the Supply Management process to ensure adequate and consistent performance of the activities entrusted to the contractors. Ecopetrol currently is certified in ISO 14001 and ISO 45001 of Icontec.

Strategic objectives and safety, process, and occupational health indicators that leverage the 2040 strategy:

- Have healthy employees, with life quality:

- Zero fatalities

- Frequency Rate of Total Recordable Cases -TRIF-: 0.3 as at 2040

- Level 1 Process Safety Incident Frequency Rate -IFSP N1-: 0.04

- Knowledge: development of HSE key capabilities.

- Agile HSE systems, learning with intelligent, transformational technology.

To achieve these objectives, in line with the HSE Management System, the organization has defined a series of management programs leading to effective management of the safety and health of workers inasmuch as its efforts and resources are applied in an organized, systematic manner. Said programs are reviewed annually, allowing for periodical update, incorporating necessary changes according to the nature of our operations, added to the needs and expectations of our clients and other stakeholders.

The organization, moreover, implements an annual training program intended for employees and contractors. For further details, see the 2024 Comprehensive Management Report.