PautaInternas

PautaInternas

Operational efficiency in water management

Operational efficiency in water management

Operational efficiency in water management

May 30, 2025

This strategic line seeks to balance the water consumption in our operations, with the provision of safe water for the ecosystem, aiming to reach water neutrality. Integrated water resource management across the business value chain creates value by enabling production and securing reserves, while ensuring the availability and continuity of water supply for current and future projects and operations. This approach strengthens the long-term sustainability of the resource and mitigates risks associated with its use.

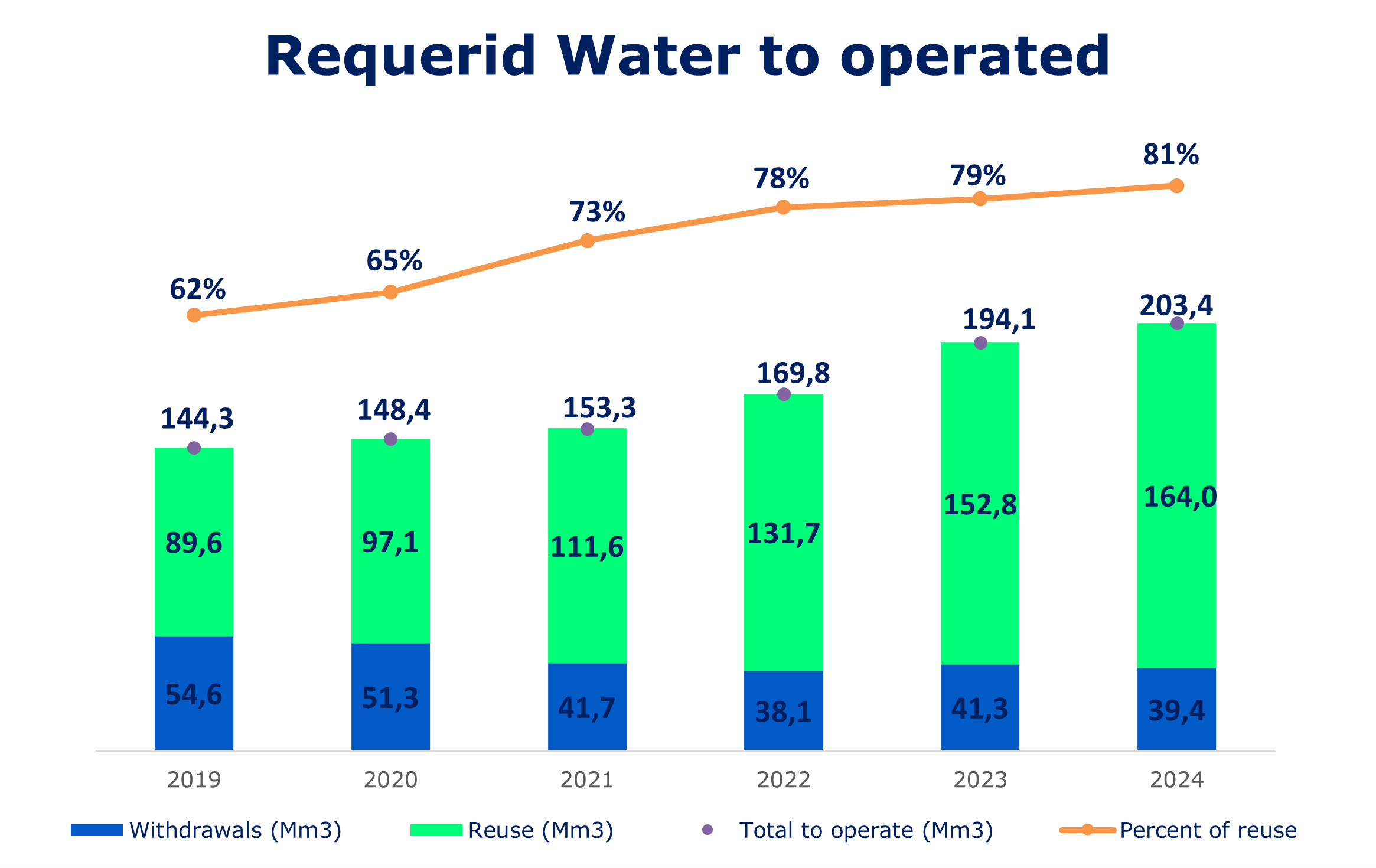

Required water to operate

In 2024, the total water volume required to develop Ecopetrol’s value chain activities was 203,4 million (m3). 81% of this volume (163,9 million m3) came from the reuse of effluents, and only 19% (39,4 million m3) was withdrawn from natural sources and/or purchased from aqueducts. The reuse rate relative to the total water required for operations has shown a year-over-year increase. In 2024, it reflects a 7% rise compared to 2023 and an 83% increase relative to the baseline year (2019). This progress has enabled a sustained reduction in freshwater withdrawals over recent years, despite growing operational water demands.

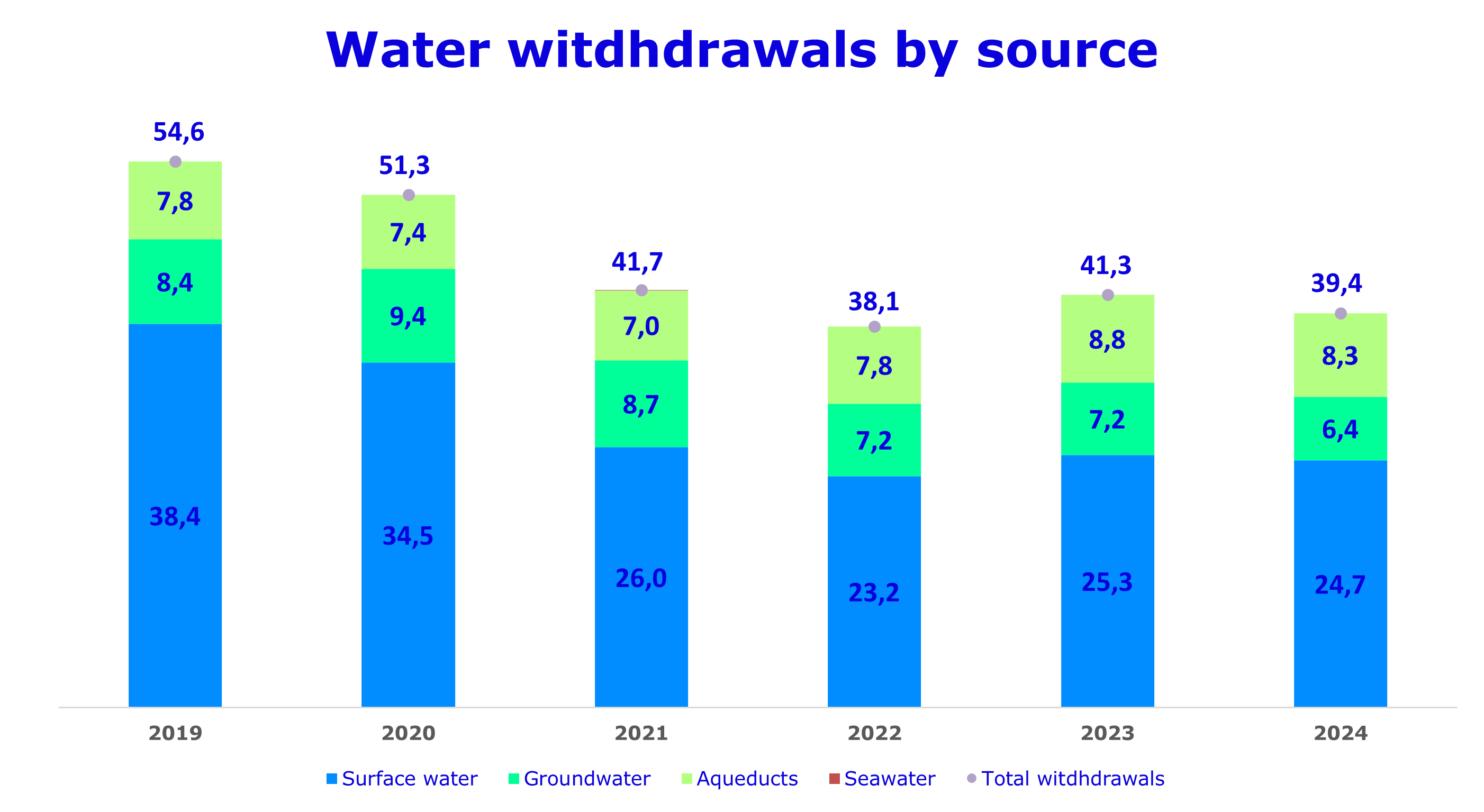

Water withdrawals from natural sources and aqueducts

In 2024, Ecopetrol withdrew 39,4 million m3 of freshwater, representing a 4,5% reduction compared to 2023. Additionally, freshwater withdrawals for industrial use decreased by 5% versus the previous year, and by 23% relative to the established baseline in 2019. This reduction is primarily attributed to increased industrial water recirculation at the Barrancabermeja and Cartagena refineries, as well as lower freshwater demand for enhanced oil recovery processes in the Casabe, Yarigüí/Cantagallo, and Tren Nare fields. However, the La Cira-Infantas field recorded an increase in water demand for recovery operations.

Of the total water withdrawn, 63% came from surface sources, 16% from groundwater, and 21% from municipal systems and third-party suppliers, through 115 intake points located across 27 watersheds. The majority of the water was used in Refining operations (72,6%), followed by Production (27,3%), with the remaining 0,1% allocated to administrative areas and the Colombian Petroleum Institute (ICP).

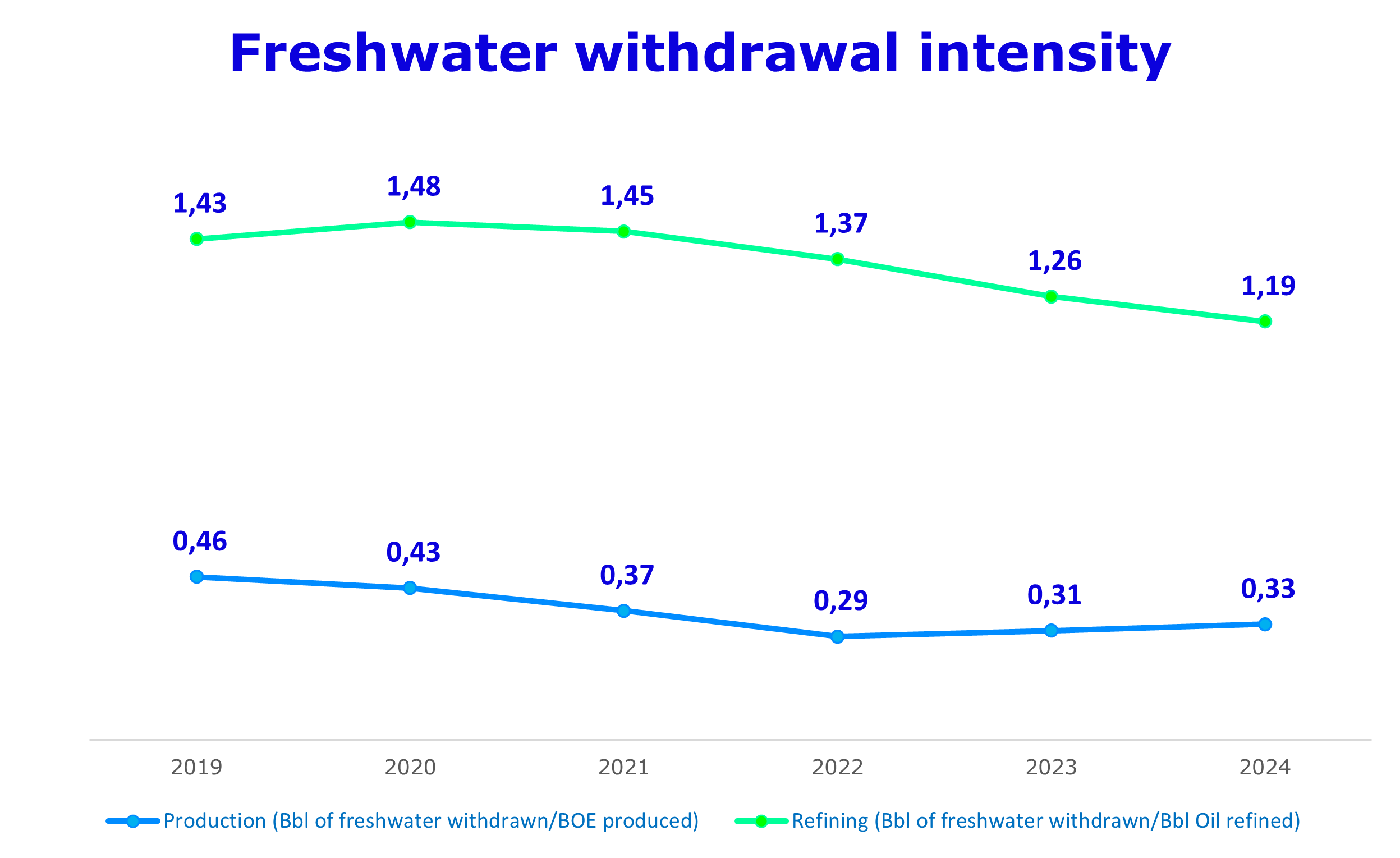

Freshwater intensity

The freshwater withdrawal intensity for the processes with the highest demand (refining and production) during the last 6 years is presented in the following chart. Compared to the previous year, the freshwater withdrawal intensity per refined barrel was reduced to 1,19 Bbl water/Bbl oil (-6% compared to 2023) due to improved efficiencies in water use and recirculation at the Barrancabermeja and Cartagena refineries. In contrast, freshwater intensity in the production segment increased to 0,33 Bbl water/Bbl oil, primarily due to higher water demand for enhanced oil recovery operations at the La Cira-Infantas field.

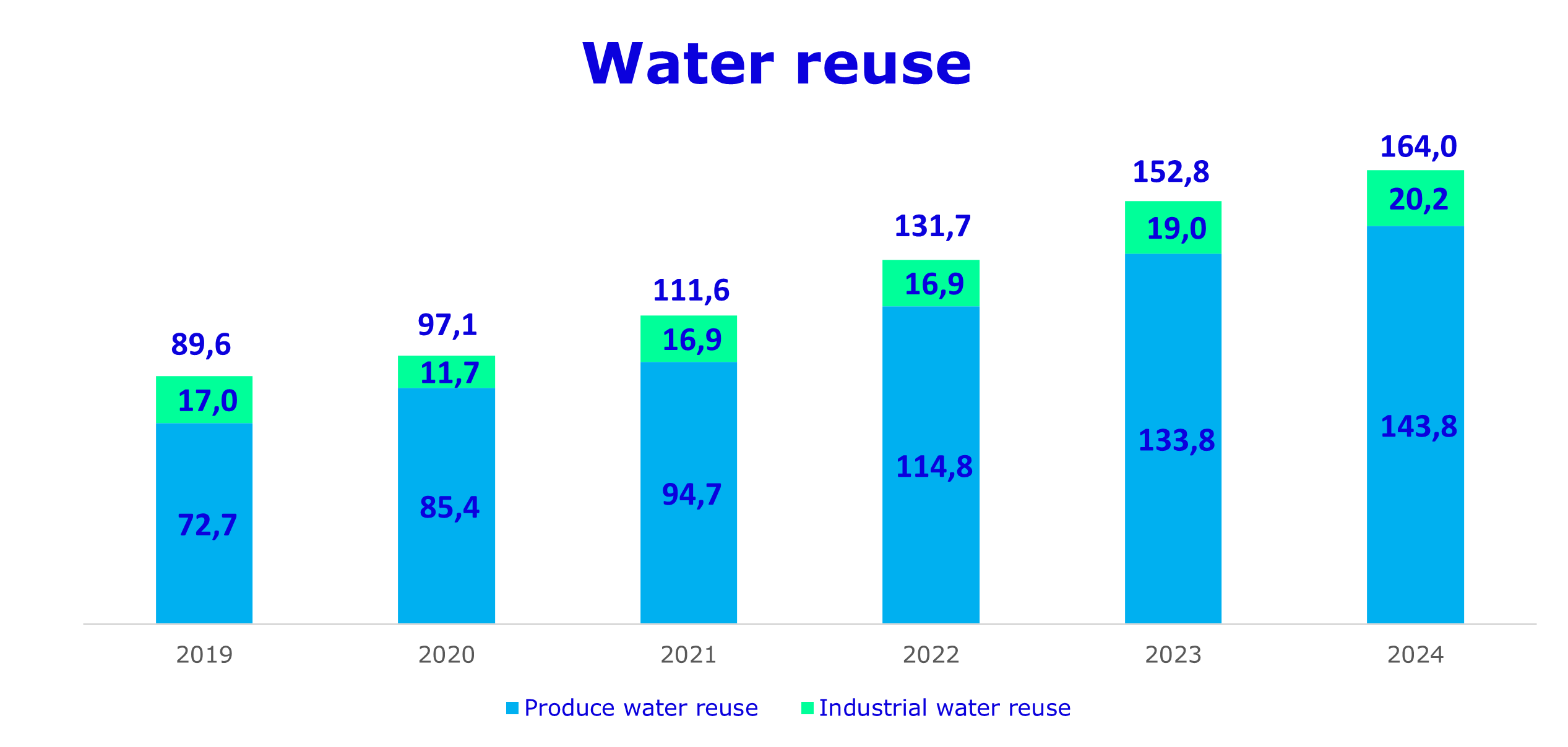

Water reuse

Ecopetrol is committed to reuse water as a strategy to reduce freshwater withdrawals and discharges. During 2024, 163,9 million m3 of water were reused equivalent to 81% of the total required to operate, which means that Ecopetrol avoided the withdrawal and/or discharge of this volume. This figure represents an increase of 7% compared to 2023.

-

Industrial water reuse

In 2024, Ecopetrol reused and recirculated a total of 20,2 million m3 of effluents resulting from the use of withdrawn water. The percentage of reuse, calculated as the relationship between the volume of reused-recirculated water and the total volume withdrawn was 51,2%, representing an 11% increase compared to 2023. This improvement is primarily attributed to the identification and implementation of new recirculation initiatives, with a significant increase in reuse within the Downstream segment and in drilling activities. In these operations, domestic and industrial wastewater following tertiary treatments such as reverse osmosis and demineralization is reused in the formulation of drilling mud, equipment washing, pump cooling systems, and other industrial applications.

- Produced water reuse

In the Upstream processes, 143,8 million m3 of produced water were reused, which represents an increase of 7% compared to 2023, mainly caused by better performance in the reinjection of production water for recovery and/or pressure maintenance in the Rubiales, Castilla, Chichimene, and Apiay assets. The percentage of produced water reuse, calculated as the ratio between the volume of reused produced water and the total produced water generated, was 29,5%.

The largest volumes of produced water reuse are concentrated in reinjection activities to maintain reservoir pressure or increase hydrocarbon production (143,4 million m3), and to a lesser extent (0,36 million m3), in the preparation of drilling mud, well maintenance, fire-fighting systems, equipment cooling, power generation (Termosuria), among others.

Effluent management

The total volume of effluents generated by Ecopetrol's operations during 2023 was 496 million m3, which includes:

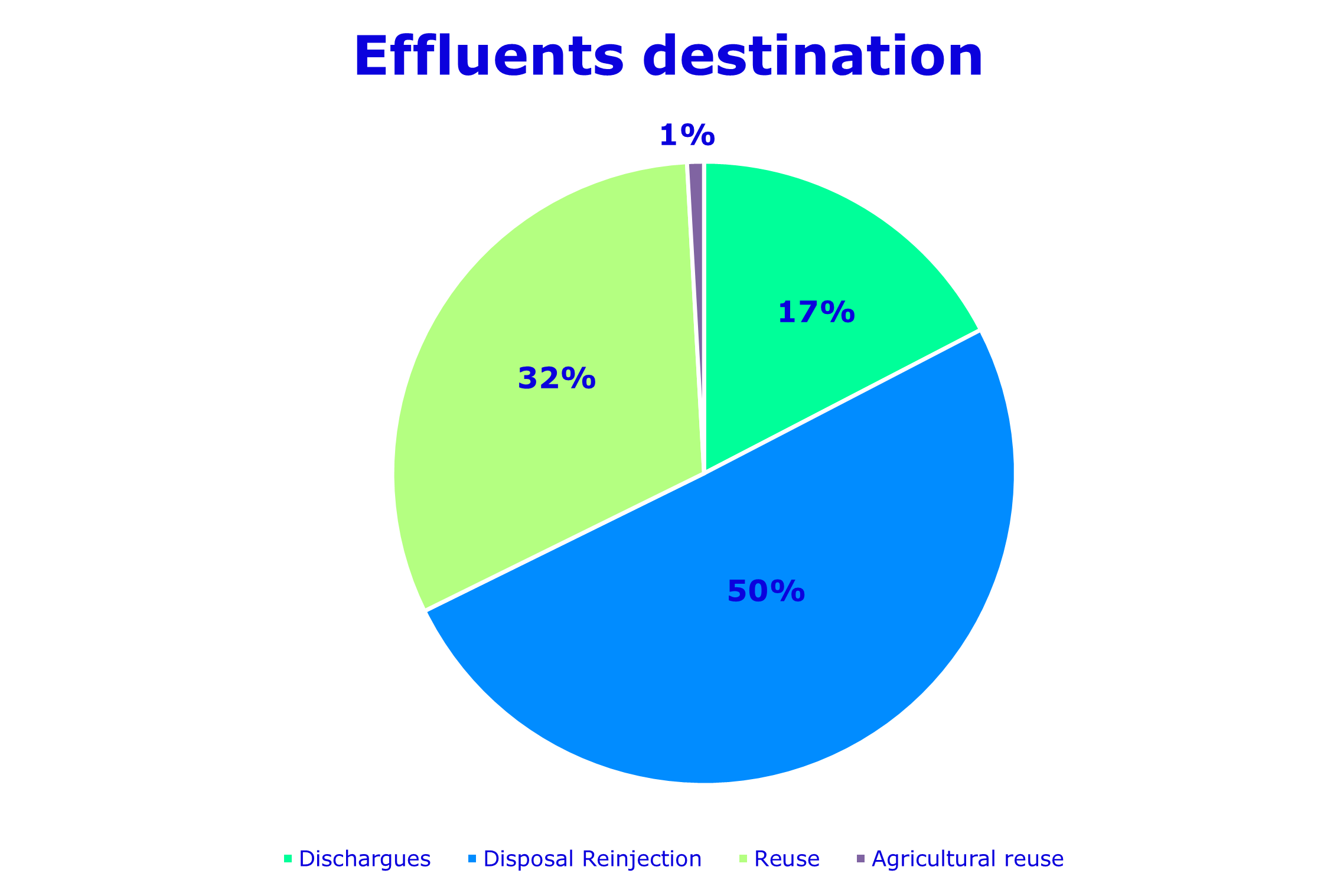

- In 2024, Ecopetrol managed 486 million m3 of produced water, accounting for 93% of the total effluents generated. Produced water is a natural byproduct of hydrocarbon extraction and does not form part of the surface hydrological cycle of the watersheds. In oil reservoirs, crude oil, gas, and water are naturally co-mingled; on average, approximately 14,8 barrels of produced water are generated for every barrel of oil equivalent extracted. This mixture is brought to the surface, where it undergoes separation processes to recover the hydrocarbons (oil and gas) and appropriately manage the residual water.

- 34,3 million m3 of wastewater (7% of total effluents), understood as the water resulting from the use of water withdrawn for industrial and domestic purposes.

Produced water reinjection

406,2 million m3 of produced water were reinjected back to the underground, which corresponds to 84% of the total produced water; 262,8 million m3 of produced water were reinjected for Disposal, and 143,4 million m3 were reinjected for oil recovery and pressure maintenance (accounted as reuse).

Reuse of produced water in agricultural activities

The reuse of produced water in agricultural activities is another alternative for wastewater management, framed within Colombian environmental regulations. During 2024, Ecopetrol reused 4,6 million m3 of produced water, 4,1 million m3 corresponds from Campo Castilla for the irrigation of forest crops in the Agroenergy Sustainability Area (ASA) and 0,5 million m3 corresponds From Campo Rubiales for the irrigation of forest crops in the Sustainability Area (SAARA), which represents 1% of the total produced water.

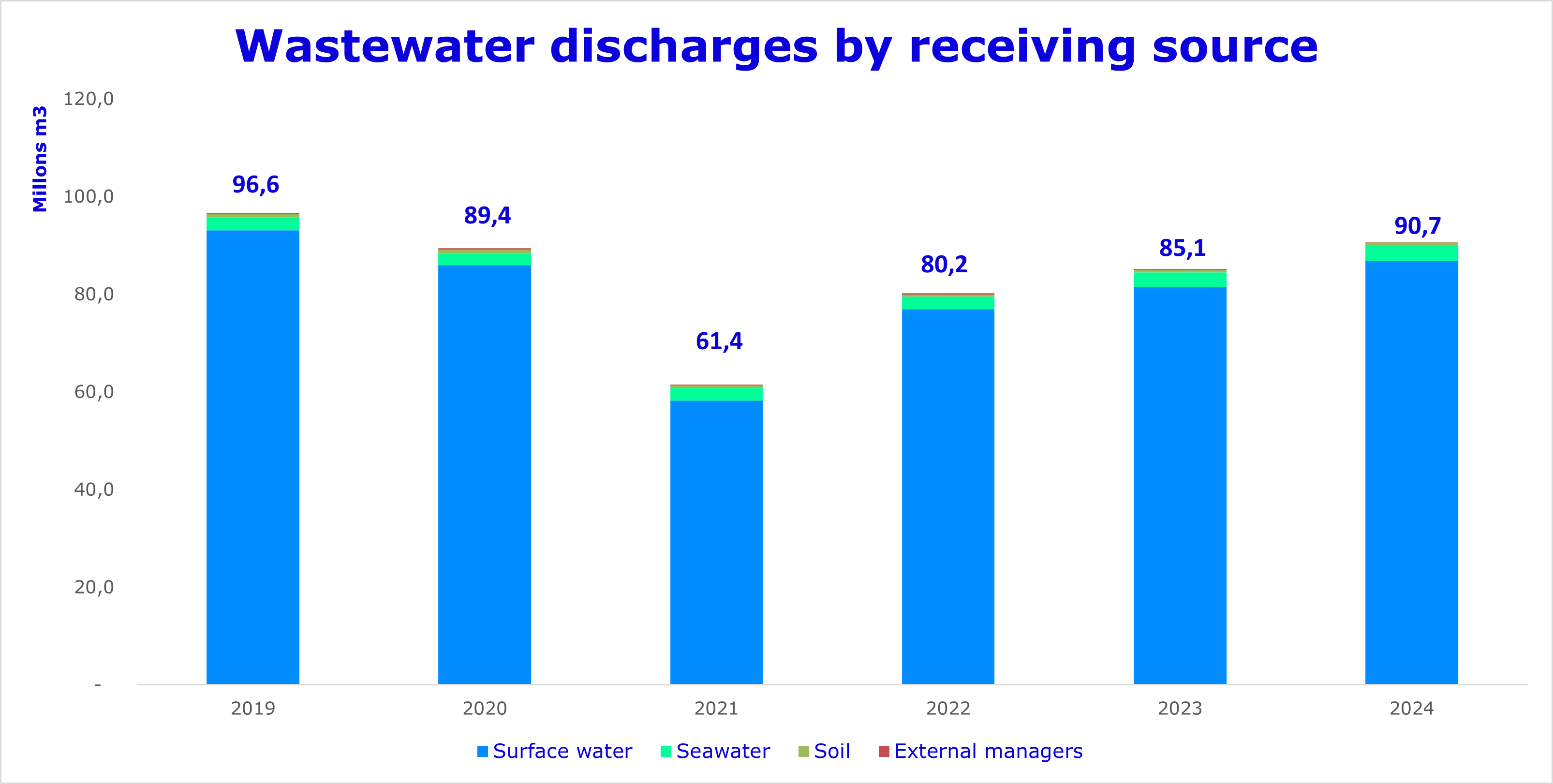

Wastewater discharge

Wastewater discharge is the last alternative used by Ecopetrol for the management of its effluents. Ecopetrol counts with discharge points authorized by the competent environmental authorities, who determine the conditions of flow, quality, and timing to ensure the discharge does not affect the natural characteristics of the receiving bodies. Before discharging to any natural receiver (surface water, seawater, or soil), wastewaters are subjected to specific treatment to remove substances of environmental interest and to comply with the maximum permissible limits established in Colombian regulations.

A total of 90,7 million m3 of wastewater was discharged, representing an increase of 7% compared to the previous year, This rise was primarily driven by higher discharge volumes from the Rubiales and Castilla fields, where the produced water is characterized by low salinity levels (<1,000 ppm TDS).

The upstream segment generated 85,1% of the total discharges (mainly produced water), the downstream segment 14,8%, and corporate areas 0,1%; 95,7% of the discharges were made to surface water bodies, 3,6% to the sea, 0,5% to the ground and 0,2% were delivered to external managers and sewers. In total, 28 basins were used for discharging wastewater.

Initiatives to improve wastewater management and treatment

With the objective of positioning water as a strategic and operational value driver for the Company, as of December 31, 2024, the ICPET (Ecopetrol's Technology and Innovation Institute) was developing the “Water Suite” initiative. This initiative focuses on the conceptualization, adaptation, and development of technologies aimed at:

- Improving effluent water quality for subsequent reuse.

- Identifying alternative water sources that do not compete with other users.

- Supporting communities in areas with limited access to water resources.

In 2024, the “Water Suite” initiative achieved the following milestones:

- Successful prototype-scale testing for chloride removal from produced water in the Suria field.

- Pilot testing of the "Polishing Beads" technology for total petroleum hydrocarbon (TPH) removal in produced water from the Castilla field.

- Pilot testing for chloride removal from sour water streams at the Cartagena refinery, enabling potential reuse and reducing freshwater demand.

- Progress in the implementation of the Tukano technology to enhance the quality of injection water.

- Execution of deep aquifer pumping tests to evaluate the feasibility of harnessing this source and assessing the quality of the available water.

- Progress in the "Guajira Water" study, including a pilot rainwater harvesting project for the Wayúu community of El Manantial.

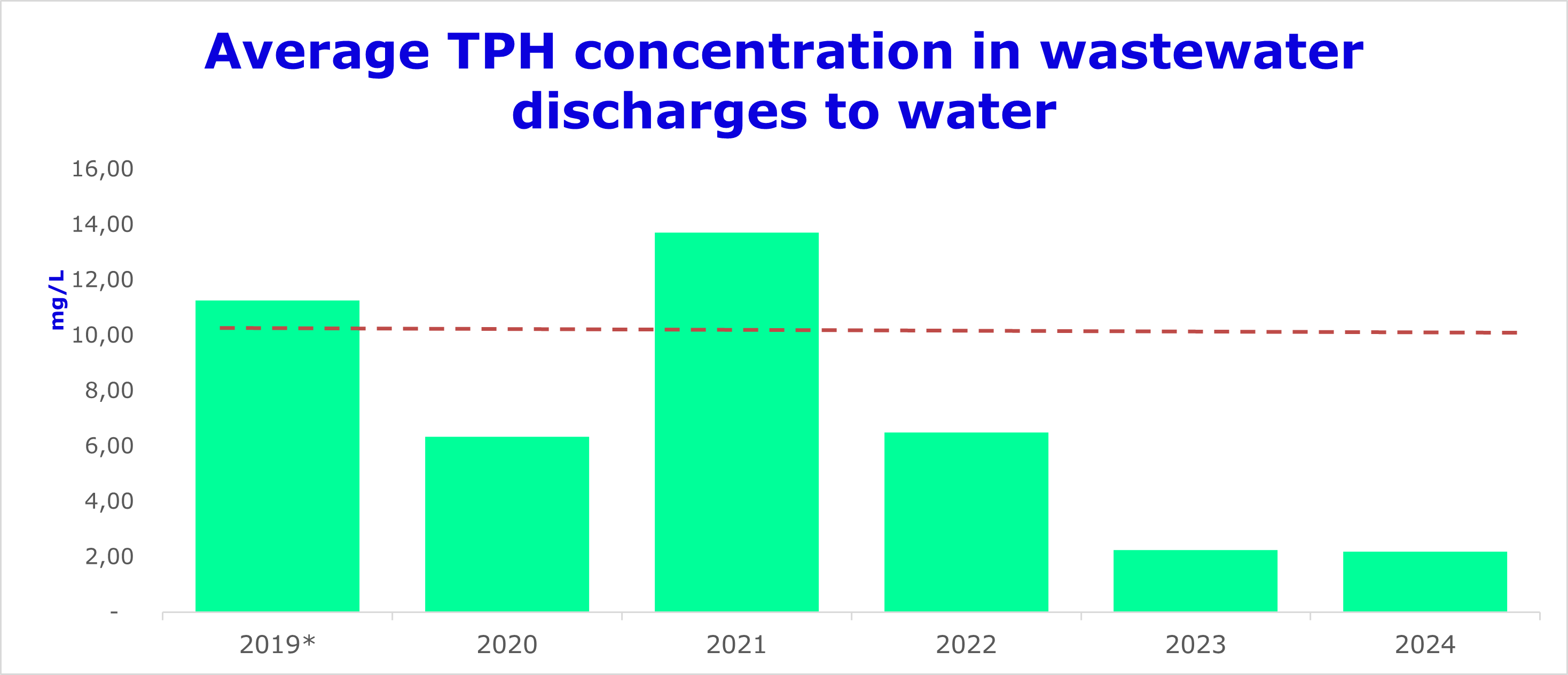

Quality of discharges

The Company has robust treatment systems, which allow for the removal of contaminants present in wastewater, and compliance with the quality standards established in environmental regulations for discharges to surface water bodies (Resolution 631 of 2015), marine waters (Resolution 0883 of 2018), or soil (Resolution 699 of 2021). For the specific case of the oil and gas sector, maximum values were defined depending on the activity within the segment, and monitoring was conducted for over 40 quality parameters. Additionally, for the definition of quality criteria, in compliance with current regulations, environmental assessments of discharges are conducted based on the assimilation and dilution capacity of the receiving bodies to minimize impacts on the resource.

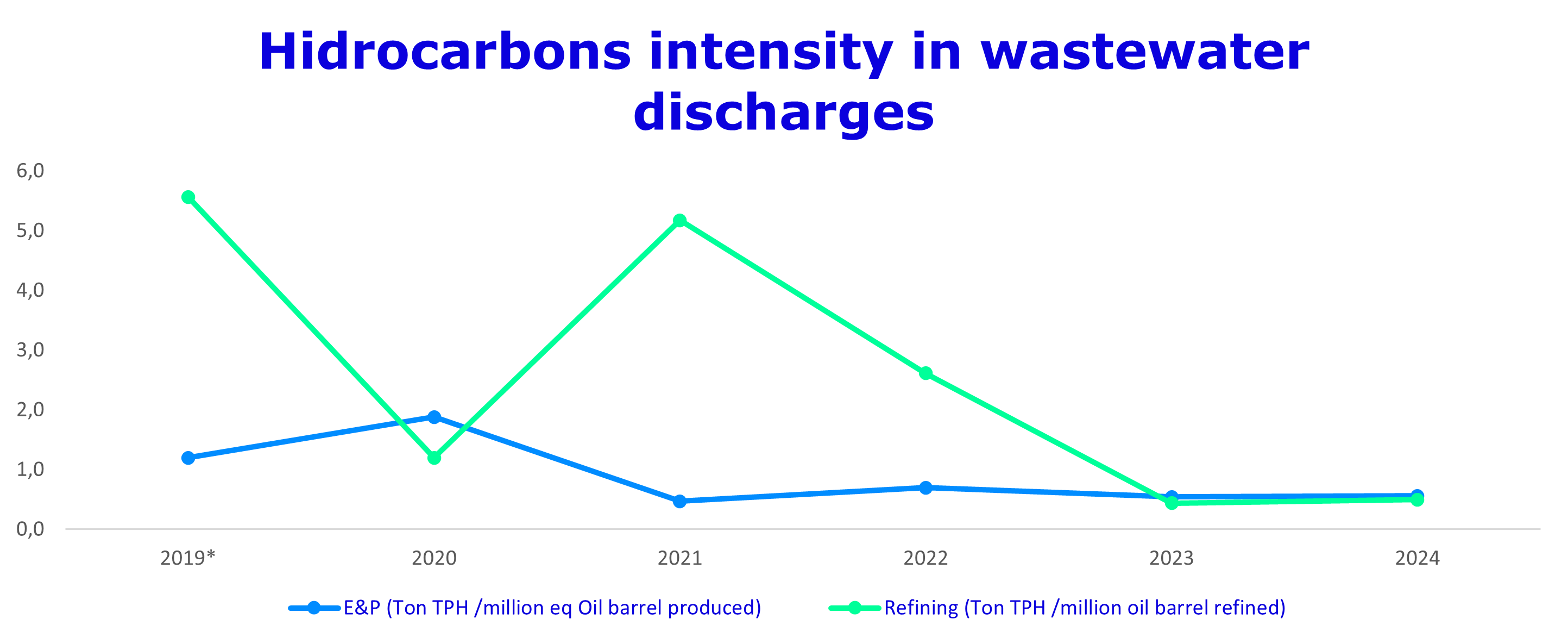

In 2024, the concentration of Hydrocarbons (measured as Total Petroleum Hydrocarbons-TPH) in Ecopetrol's discharges to water, registered an average value of 2,2 parts per million. For Ecopetrol, the reference value is 10 parts per million, which has been achieved in 100% of Ecopetrol’s assets within the terms established by the environmental authorities. In terms of intensity, in the E&P segment, an equivalent of 0,6 tons of hydrocarbons contained in wastewater were discharged for every million barrels of oil equivalent produced, while for the refining segment, the value was 0,5 tons per every 1 million oil barrels refined.

These years are included in the transition regime allowed by environmental authorities to adjust the treatment systems to comply with the new standard for discharges to surface bodies.

Water consumption

Water consumption is defined as the difference between the volume of water withdrawals and the volume of water that is returned to the natural environment. Using the CDP Water Security Reporting Guidance (2020) methodology, the estimated water consumption in 2023 was 19,5 million m3, which is equivalent to 4% of total inputs. Most of the consumption is recorded in the refining segment due to evaporation losses.

Water related risks

Water is a vital resource for Ecopetrol's operations and projects. For this reason, water-related risks are continuously identified, in possible scenarios that may affect the continuity of operations are evaluated and anticipated. In this sense, a business risk called "Inadequate response to challenges associated with climate change, water, and biodiversity" — Under this category, water-related risks, their root causes, and potential consequences are identified annually to anticipate scenarios that may impact operational continuity. Accordingly, the Company implements Key Risk Indicators (KRIs) to monitor variables related to water availability across its assets and establishes mitigation and response actions to reduce its exposure to such risks.

Regarding physical risks, Ecopetrol uses the World Resources Institute (WRI-Aqueduct) methodology and identifies its facilities located in areas with potential water stress, when the water use (ratio between water demand and available surface supply of the sub-basin) is greater than 40%, using official information published in the 2022 National Water Study by IDEAM. In 2024, 8,4 million cubic meters of freshwater were withdrawn from sub-basins with this condition, which represents 21% of the total water withdrawn by the company. On the other hand, 12,1 million m3 of produced water was generated (11,6 Mm3 were reused for oil recovery), and 3,3 Mm3 of wastewater was discharged (including produced water). Based on these figures, the estimated consumption in water-stressed areas was 5,1 million m3. Ecopetrol continues to develop initiatives for reducing the dependence on freshwater at these facilities.

Ecopetrol continues to advance initiatives aimed at reducing its dependence on freshwater across its facilities. In 2024, the Company achieved a 30% reduction in freshwater withdrawal in water-stressed areas compared to 2023. This improvement was primarily driven by increased water use efficiencies at the Cartagena refinery and enhanced identification of water-stressed zones, supported by the application of hydrological indicators at the Subsequent Subzone (SSZ or Level 4 hydrological planning) when available in the Watershed Management and Land Use Plans (POMCA). In basins lacking formal watershed planning, Ecopetrol applied indicators at the Hydrographic Subzone (HSZ or Level 3) as defined in the National Water Study (2022).

Water use index by sub basin

- Direct to the Caribbean · 1206

The Cartagena Refinery purchased 8,3 Mm3 of raw water from the Cartagena aqueduct, which is equivalent to 3,7% of the available supply from the sub-basin. As a strategy to minimize water use, the Refinery reuses 64% of the purchased water. - Juncal River · 2109 and Fortalecillas River · 2111

41,2 Mm3 of freshwater was withdrawn to supply the Neiva, Tello, and Río Ceibas oil fields. In these fields, 94% of the produced water is reused for oil recovery, and freshwater is extracted from deep underground wells, avoiding pressure on the surface resources. - Yaguará River · 2108

19 Mm3 were withdrawn from the Betania Dam to supply the Yaguará oil field. This value represents 0,004 % of the available water supply of the subbasin. In this facility, 100% of the produced water is reused.

. . .