PautaInternas

PautaInternas

buscador_1

buscador_1

Current management

Current management

Current management

Jan 30, 2026

Adicional Management of Incident Prevention and Environmental Remediation of Areas

Our Commitment to Prevention and Environmental Management

Ecopetrol’s environmental strategy includes, as one of its eight (8) pillars, the prevention and environmental remediation of areas. This pillar is aimed at preventing, mitigating, and managing potential impacts on the environment arising from hydrocarbon spills or other hazardous substances within the Company’s areas of operation.

This pillar is grounded in proactive risk management through the identification, assessment, and control of potential events with environmental impact associated with the organization’s various lines of business, thereby strengthening prevention capabilities and contingency response.

Ecopetrol’s management approach goes beyond a strictly ecological scope and is integrated with other strategic areas of the organization. Accordingly, the Company strengthens its operations through asset integrity and process safety plans, which include, among others:

Our Commitment to Prevention and Environmental Management

In compliance with Resolution 1767 of 2016, Ecopetrol mandatorily reports to the environmental authority all events that result in any level of environmental impact, regardless of their origin, magnitude, or the type of substance involved. Additionally, depending on the nature of the event, the Company submits the corresponding reports to other competent authorities and entities, such as the Regional Autonomous Corporations, the National Hydrocarbons Agency (ANH), the General Maritime Directorate (DIMAR), as well as operational support agencies, among others, thereby ensuring a coordinated response in accordance with applicable regulations.

Additionally, in line with international standards such as SASB and the Dow Jones Sustainability Index (DJSI), the Company reports separately on incidents involving volumes greater than one (1) barrel, in accordance with the criteria established by these standards. This information is verified by an independent third party and published on the corporate website under the Management and Sustainability Reports section, ensuring transparency and traceability for the market and stakeholders.

The Integrated Management Report also includes total volumes of hydrocarbons spilled, providing a comprehensive view of environmental performance in this area.

Historical and current information on incidents with environmental impact involving Ecopetrol S.A. can be consulted in the Historical behavior of incidents section of the Company’s website.

Incident Classification

Incidents with environmental impact may be classified in different ways depending on their origin, type of substance, and volume, which may lead to misinterpretations if the applicable reporting standard is not taken into account. Among the main categories are:

Therefore, it is essential to identify the relevant category when analyzing any figures, ensuring a proper interpretation aligned with the applicable technical and regulatory standards.

Operational or Technological Incidents

Ecopetrol has prevention mechanisms based on risk analyses and maintenance plans and programs that ensure the integrity of its infrastructure. Nevertheless, in the event of an incident with environmental impact, the Company immediately activates its Emergency and Contingency Plan (PEC) to contain the source, mitigate the impact, and prevent further damage.

Subsequently, cleanup and remediation activities are carried out, as applicable, in accordance with the guidelines of the National Contingency Plan for Hydrocarbon, Derivative, and Hazardous Substance Spills, established by Decree 1868 of 2021.

In the case of operational-origin contingencies, actions include prevention, mitigation, correction, decontamination, and environmental restoration.

All cleanup and remediation actions, as applicable, are reported to the environmental authority through ANLA’s VITAL platform, by means of interim and final contingency reports, to the corresponding Environmental Corporations, as well as through the Environmental Compliance Reports (ICA).

Incidents Caused by Third Parties

Incidents caused by third parties refer to intentional, unforeseeable criminal acts beyond the company’s control, such as theft and/or attacks against infrastructure. Ecopetrol is a victim of these events, which affect transportation, production, and operational continuity.

Nevertheless, the company has deployed all necessary resources to address contingencies and mitigate impacts during emergencies, in accordance with applicable regulations.

Although Ecopetrol S.A. is not responsible for this type of event, it has achieved a sustained reduction in incidents caused by third parties: between 2015 and 2025, cases decreased from 101 to 37, representing a 63.37% reduction over the past ten (10) years.

Regulatory Framework for Incidents Caused by Third Parties

In accordance with the National Contingency Plan, adopted through Decree 1868 of 2021, the responsibility of the industry in the event of incidents caused by intentional acts by third parties against infrastructure or the means of transportation of hazardous substances is to respond to the contingency, implement prevention, mitigation, or corrective actions during the emergency, and control events that may affect human health, natural resources, the environment, and the landscape.

This scope does not include the execution of decontamination and environmental recovery actions in areas impacted by acts attributable to third parties; therefore, the removal of spilled hydrocarbons does not reach 100%.

The conduct giving rise to this type of incident is classified under Colombian legislation as the illegal appropriation of hydrocarbons (Article 327A of Law 1028 of 2006) and terrorism (Article 343 of Law 599 of 2000 – Criminal Code). Consequently, environmental recovery actions arising from these acts are the responsibility of their perpetrators, without prejudice to the immediate response carried out by Ecopetrol S.A. to contain and mitigate impacts during the emergency.

In summary, the actions that, by law, any company must carry out in the event of an environmental incident, depending on its origin, are as follows:

*Environmental recovery is not always required; this obligation depends on factors such as the existence of actual environmental damage or impacts that are not fully reversed through primary cleanup, an explicit requirement from the environmental authority, obligations established in environmental management instruments, exceedance of physical-chemical limits, the definition of recovery measures in the final report submitted through VITAL, or the identification of additional actions necessary to restore the environment or prevent further impacts, among others.

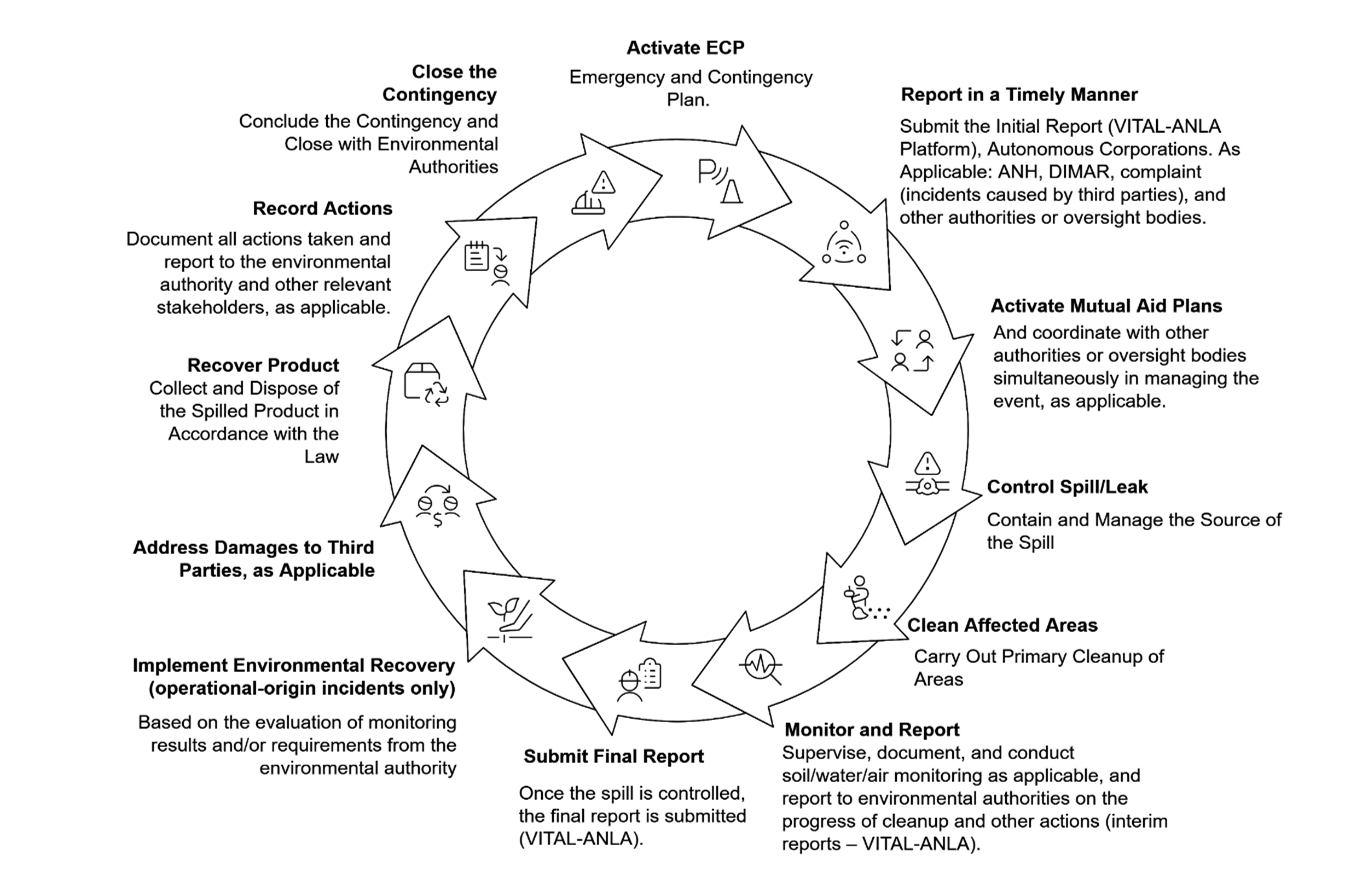

Framework for Action in the Event of Incidents Affecting the Environment

Some of the actions described below are carried out simultaneously during an incident, while additional activities may be required depending on the characteristics of the incident.

Accordingly, Ecopetrol S.A. deploys and carries out the aforementioned activities, including spill control, cleanup, and environmental recovery.

All incidents affecting the environment have been timely reported to the competent environmental authorities, including follow-up on the progress of the implementation of the respective environmental recovery plans, where applicable, and in compliance with the monitoring and oversight requirements issued by those authorities.

Remediation of areas affected by hydrocarbons and their derivates at Ecopetrol

Introduction to the remediation of affected areas and improvement of the condition

Ecopetrol has an environmental strategy that defines eight management pillars, one of which is Prevention and Remediation. This strategic pillar seeks to prevent potential environmental impacts from spills of hydrocarbons or other hazardous substances in Ecopetrol’s operating areas. This is achieved through proactive risk management, continuous improvement, and the prioritization of environmentally sensitive area.

Additionally, this pillar also focuses on the remediation and improvement of areas impacted by hydrocarbons and/or their derivatives, such as the Unresolved Environmental Impacts (IANR – Impactos Ambientales No Resueltos). This is accomplished through the incorporation of cutting-edge technology in the diagnosis and recovery processes, which enables the progressive reduction of impacts and the environmental recovery of these sites, in compliance with applicable environmental regulations.

1The 8 pillars of environmental management at Ecopetrol are: Prevention and Remediation, Comprehensive Waste Management, Clean Air for the Environment, Biodiversity and Ecosystem Services, Water Neutrality, Circular Economy, Environmental Planning and Compliance, and Climate Action

1. What is an unresolved environmental impact (IANR)?

Definition: An IANR (Unresolved Environmental Impact) is a physical space or site with the presence of hydrocarbons or other substances in concentrations exceeding current reference levels (Louisiana 29B). These are found in soils, sediments, groundwater, and/or floodable areas and are associated with value chain processes (exploration, production, transport, or refining). These impacts were generated by old operations in assets that commenced activities prior to Law 99 of 1993, and are currently the responsibility of Ecopetrol.

Why do unresolved environmental impacts exist at Ecopetrol?

Oil activity in Colombia began over 100 years ago, with the Middle Magdalena Valley region being one of the first zones where oil exploration and production activities were developed in the country. For 75 years (prior to Law 99 of 1993), oil operations lacked a rigorous or specific environmental regulatory framework such as the current one, and activities were largely conducted by transnational companies operating under the regulations of the time.

Tropical Oil Company – Troco Oil Well (1920–1930 Period), located in Ecopetrol’s current La Cira Field

Ecopetrol currently to corporate principles for environmental stewardship and has an environmental strategy aimed at preventing and mitigating potential impacts on ecosystems.

Since the entry into force of Law 99 of 1993, Ecopetrol, with the support of the community and environmental authorities, began the ** identification of environmental impacts** caused by hydrocarbons and their derivatives within its areas of influence. This also included defining strategies for characterization, intervention, and reporting through environmental compliance reports.

What are not unresolved environmental impacts?

Unresolved Environmental Impacts (IANR) do not include all sites with the presence of hydrocarbons or other substances associated with:

- Natural Seeps, Hydrocarbon emanations originating from natural conditions.

- Environmental incidents with environmental impact, according to the applicable environmental legal framework.

- Environmental Liabilities, as defined by law (Article 2, Law 2327 of 2023).

- Sites authorized for the disposal and treatment of hydrocarbon-impregnated waste.

Current IANR status at Ecopetrol

Since the entry into force of Law 99 of 1993, Ecopetrol, with the support of the community and environmental authorities, began the identification of environmental impacts caused by hydrocarbons and their derivatives within its areas of influence, as well as the definition of strategies for characterization, intervention, and reporting, through environmental compliance reports. Consequently, from the early 2000s to date, Ecopetrol continues with the identification, diagnosis, and recovery of sites affected by hydrocarbons or their derivatives in the areas where it develops its operations or where environmental instruments are under its responsibility. This is part of a process of continuous improvement focused on progressively reducing impacts and risks to ecosystems, in harmony with the environment and stakeholders.

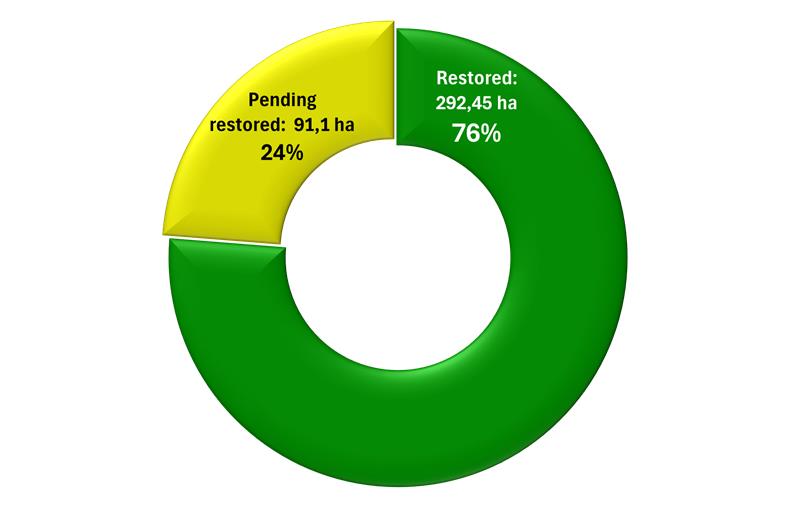

As a result of these efforts, Ecopetrol has identified 286 IANR sites to date, corresponding to 383.5 hectares (ha), of which:

Restored: 292,45 ha, equivalent to 76% of the total

Pending restored: 91,1 ha, equivalent al 24% of the total.

2. Diagnosis of areas affected by hydrocarbons at Ecopetrol

For the diagnosis of areas impacted by hydrocarbons, Ecopetrol proactively incorporates a new technique called advanced environmental geophysics.

2.1. Advanced environmental geophysics

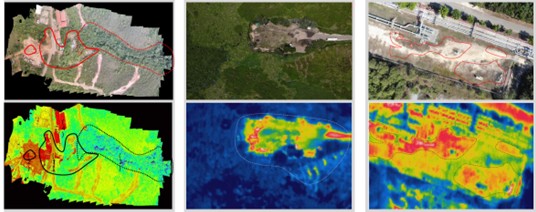

The advanced environmental geophysics is a non-intrusive, multidisciplinary diagnostic model that, through the integration of cutting-edge technologies like remote sensors, allows for the detection of anomalies or impacts in the soil, sediments, or water bodies with high precision and reliability. This model can be combined with other techniques, such as:

- Aerial methods: This involves taking a series of aerial photographs using an Unmanned Aerial Vehicle (UAV), equipped with an infrared, thermographic, and multispectral digital camera, operating in the morning hours and following a predetermined grid. This technique makes it possible to precisely locate alterations caused by chemical differences (hydrocarbons) in the soil at the surface level and down to a depth of up to 2 meters.

Graphical outputs of advanced environmental geophysics using aerial methods.

- Terrestrial methods: Another technique involves the on-site use of ground-penetrating radar (GPR) or a profilometer to define the geomorphological and geological structure of the subsurface. This allows for the definition of deeper anomalies and provides a greater degree of detail regarding the points of highest hydrocarbon concentration at depths between 6 to 10 meters.

Ground-Penetrating Radar Perfilometer

In addition to modern techniques, conventional techniques are also performed, such as physicochemical characterization by means of test pits.

2.2. Physicochemical characterization

This characterization is performed using test pits (excavations) in the soil, based on primary information obtained from the communities or from the operation regarding the possible location of hydrocarbon presence for its identification and delineation. These test pits, used for sampling and characterizing hydrocarbons in the soil, are carried out randomly spaced apart (approximately 10, 50, or up to 100 meters) with inherent limitations regarding topography, area, and depth, but which allow for the precise measurement of hydrocarbon concentrations in the soil.

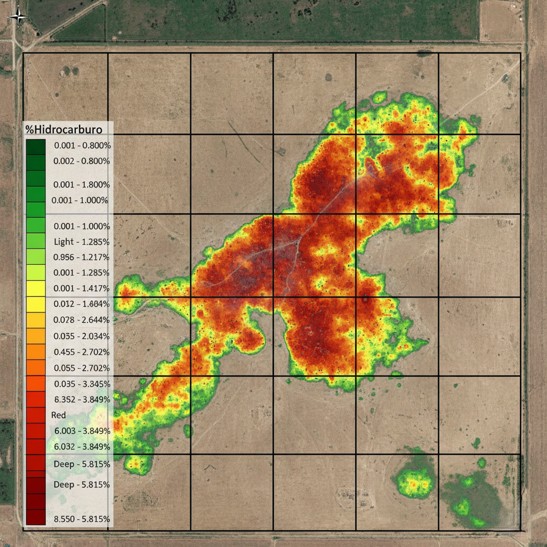

By implementing cutting-edge techniques such as environmental geophysics using drones or GPR, and integrating them with conventional techniques for identifying and quantifying hydrocarbon concentration in the soil (such as test pits and field monitoring), we obtain a continuous image of the impacted area. This precisely pinpoints the location of anomalies, hot spots (areas of highest concentration) associated with the presence of hydrocarbons in the soil, sediments, or water bodies with high reliability. This integrated approach achieves a 55% reduction in uncertainty compared to previously identified areas.

3. Treatment of areas affected by hydrocarbons at Ecopetrol

Once the IANR is identified, diagnosed, and delineated, the information obtained is analyzed and cross-referenced with the territory's environmental and social data to determine the following:

- Extent of the affected areas.

- Presence of impacts in wet areas or aquatic environments: Such as natural or artificial water bodies, seasonal floodplains, etc.

- Presence of impacts in dry areas: areas without water presence.

- Contaminant type: Crude oil, refined products, whether it has high API gravity or low API gravity.

- Contaminant state: liquid, viscous, or solid.

- Concentration: Hydrocarbon level in the soil and location of hot spots.

- Presence of exclusion zones and/or environmental determinants.

- Presence and proximity to housing or areas of social interest.

- Any other information that the recovery team considers relevant for each specific case may also be incorporated.

3.1. Risk assessment

The risk assessment is developed using the previously identified information. This allows for a comprehensive evaluation of the risk scenarios associated with both the presence of hydrocarbons in the impacted area and the planned intervention and recovery activities, which could compromise the effectiveness or even the relevance of the recovery actions.

Structured and multidisciplinary methodologies are used for this analysis, such as the bow-tie method for risk identification. This allows for a comprehensive description of the causes, the central risk event or boundary, the consequences, and the required controls.

Once the risks have been identified, they are evaluated and assessed using the Ecopetrol Risk Assessment Matrix (RAM), which establishes the resulting risk level from the probability-consequence combination. This allows for the assessment and prioritization of risks according to their rating and the establishment of risk treatment plans prior to or during intervention and restored activities.

3.2. Intervention and restored of áreas affected by hydrocarbons

The intervention and recovery of impacted areas constitutes an integral strategy for the remediation of sites affected by hydrocarbons or their derivatives, based on the area's characterization, risk assessment, and compliance with the environmental requirements demanded by the environmental authority.

To carry out the recovery, Ecopetrol performs the following activities:

- Delineation and subdivision of the affected area: Based on the area identified by investigative sampling and/or Advanced Environmental Geophysics, the polygon of the impacted zone is delineated. This corresponds to the maximum extent of the plume, including the different affected zones. The area is then subdivided into smaller areas ranging between1500 m2 and 2000 m2, each with its corresponding codification.

Example of delineation and subdivision of a hydrocarbon affected area.

Biological characterization and management: The vegetation cover of the intervention area is characterized, differentiating between herbaceous and shrub vegetation, and determining if the inventoried individuals are susceptible to forestry utilization. Furthermore, observation and free search surveys are conducted, with emphasis on vertebrate faunal groups (birds, mammals, reptiles, and amphibians), defining the requirements for deterrence and relocation.

Ensuring compliance with environmental management measures: The application of the environmental management measures contained in the environmental instrument and applicable during the intervention is validated (e.g., solid and liquid waste management, topsoil stripping, revegetation, among others).

Site preparation: This involves the conditioning of temporary access roads (haul roads) and the construction of a temporary camp for the storage of materials, tools, waste, etc.

Rainwater and runoff management: If required, controlled drainage systems are constructed on site (e.g., ditches, grease traps, and sediment traps).

Preparation of bioremediation biocells, batches, or biopiles: This involves the creation of cells, batches, or piles in the intervention area using machinery, with dimensions determined by the intervention design and site conditions. The material is then extracted to proceed with spreading and homogenization.

Application of bioremediation products: We primarily use microbiological cultures produced from native strains, adapted for the rapid biodegradation of hydrocarbons, for which Ecopetrol holds patents on biotechnological products. Furthermore, their application depends on the volume of material and the hydrocarbon concentration in the soil.

Biopolymers may also be used, particularly lignocellulosics, which contain a porous structure that facilitates the interaction between degrading bacteria, hydrocarbons, and available nutrients in the solid medium, optimizing contaminant biodegradation. This includes the use of surfactants, which reduce the surface tension at the oil-water interface, solubilize polar and non-polar molecules, thereby releasing hydrocarbons trapped in soils and sediments.

Mechanical aeration: Once the bioremediation products are dosed, oxygen is incorporated through enveloping movement with the assistance of a backhoe. The duration of this activity will be determined by the hydrocarbon concentration to be degraded or by environmental conditions.

Mechanical aeration process

Process monitoring and control: A continuous monitoring and real-time adjustment system is established through 24/7 operational physicochemical monitoring. This allows for the continuous evaluation of parameters such as hydrocarbons, using equipment like retorts (equipment for measuring hydrocarbon content in soil), which make it possible to obtain field data in less than one hour and maintain daily control of the process.

Analysis using retort equipment

Based on these daily hydrocarbon results, real-time adjustments are made to the treatment dosage, ensuring precise and efficient application until the reference limit of the Louisiana 29B standard of 1% (w/w) in hydrocarbon content as TPH (Total Petroleum Hydrocarbons) is reached.

Verification monitoring: Once the intervened area achieves compliance with the reference limits for the hydrocarbon parameter via the retort method ($TPH ≤ 1\%), the closure monitoring and verification of effective recovery proceeds. This is carried out by an environmental laboratory accredited by IDEAM to validate that the hydrocarbon concentrations in the soil are below the 1% concentration limit.

Site Recontouring and Vegetation Cover Recovery: These are the necessary works for recontouring the landform to prevent erosion processes. This also includes the application of fertilizers, the conditioning of the area, and the recovery of vegetation cover, in accordance with the land use defined in the environmental planning instruments.

Innovation in the techniques used for the recovery of hydrocarbon-impacted areas has allowed Ecopetrol to optimize bioremediation times, reducing them from 90 days/m3 of soil to an average 15 days/m3 in all areas where these activities are carried out. This achievement positions Ecopetrol at the forefront of biotechnology implemented for the recovery of areas affected by hydrocarbons or their derivatives.

A practical example of the results obtained through the application of the aforementioned biotechnologies in an impacted area is shown below:

Hydrocarbon-Affected Area: Before and After Recovery

. . . .