Pauta-Ambiental-En

Pauta-Ambiental-En

buscador

buscador

Environmental Program

Environmental Program

Environmental Program

Mar 8, 2023

Ecopetrol fosters environmental best practices among its suppliers, implementing the environmental procurement model in five axes and five transverse pillars. These best practices are the base of the roadmap designed to achieve the goals that impact the Ecopetrol’s Group TESG strategy and the commitment with energy transition.

The axes of the Environmental Sustainability Program for the supply chain are:

Decarbonization

↓27% supply chain GHG EMISSIONS (2030)

Materials and waste

↓ Waste generation

Circular economy model - triple impact

Zero water discharges

↓20% water consumption in prioritized non-industrial facilities

Indirect water footprint

Natural capital

Net zero deforestation

Supply chain net possitive impact

Environmental legal compliance

Para lograr las metas trazadas en cada uno de los cinco (5) aspectos temáticos, el Programa Ambiental en la Cadena de Abastecimiento y Servicios se gestiona a través de diferentes palancas transversales:

Procurement

- Environmental criterio as supplier’s selection factors

- Environmental clauses

- Supplier’s performance assessment

Technology and information

Data collection ➡ Processing ➡ Reporting ➡ Analytics ➡ Information repository

Human resources

- Networking

- Training

Relationship management

- Segmentación de aliados

- Programa de desarrollo de proveedores

Management control system

Ecopetrol applies the decarbonization cycle with suppliers, impacting Scopes 1, 2 and 3 of the company’s GHG inventory. The decarbonization cycle starts collecting GHG emissions data from suppliers, achieving decarbonization goals commitment for contracts, and implementing reduction and compensation emissions initiatives with suppliers.

As follows are the main outcomes of each stage of decarbonization cycle.

a. Descarbonization cycle

GHG emissions calculation

The baseline of the GHG emissions inventory of the supply chain is 835.492 tCO2e for 2019.

Continuously, the GHG inventory for the supply chain is improved: In 2022, Ecopetrol collected GHG emissions data from 234 suppliers, corresponded to 40% of total spend and 45% of total GHG emissions inventory of the supply chain.

Reduction and compensation of GHG emissions

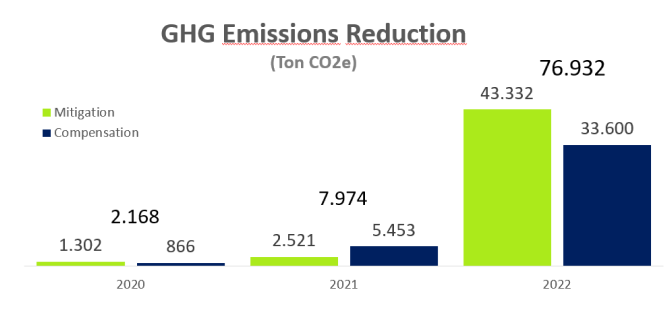

From 2020, the GHG emissions have been reducing through mitigation initiatives like energy efficiency, circular projects, sustainable mobility for employees, which includes low emissions vehicles, vehicle fleet optimization, and the portfolio “Move different” with 7 alternatives so that employees travel to company’s offices in an environmentally friendly manner.

At the end of 2022, 135 suppliers mitigate GHG emissions in the contracts operation, correspond to 48% of total spend.

On the other hand, compensation actions have been taken through the acquisition of carbon credits by suppliers, mainly in Nature based Solutions (NbS) projects, that also brought social co-benefits for Colombia.

In total, during 2022 76.932 tCO2e were reduced, correspond to 9,2% of total GHG inventory of supply chain, 865% higher than 2021 GHG emissions reduction.

a. Supplier engagement

To achieve outcomes in GHG emissions inventory and reduction for the supply chain implies supplier engagement in Ecopetrol 2040 TESG strategy. This supplier engagement includes sensibilization and educational summits; during 2022, 278 suppliers, that represented 1478 contracts, participate in several climate change meetings:

First TESG Congress for the supply chain

Two (2) supplier summits dedicated to climate change and water (160 participants)

One (1) supplier summit about decarbonization for the transport sector (90 participants)

One (1) supplier summit related to GHG compensation (220 participants).

Complementary to summits, Ecopetrol started individual conversations with prioritized suppliers to apply the decarbonization cycle in each contract: Estimating, reducing, and compensating emissions.

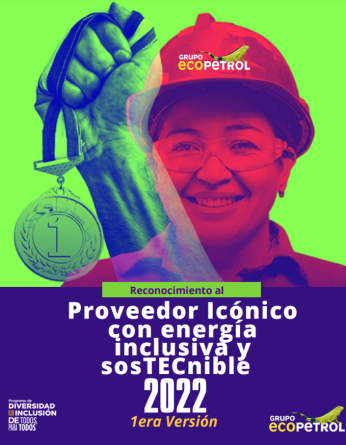

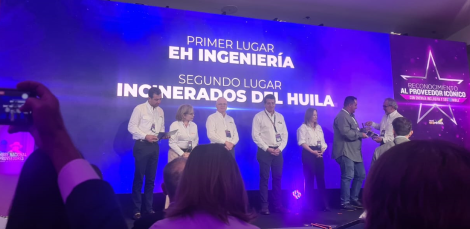

During 2022, Ecopetrol launched the first version of Recognition to Iconic Supplier with inclusive and TESG energy with the objective of highlight the best practices in inclusion, equality, environmental care, and innovation and technology in the supply chain. One of the recognized categories was environmental care, in which the application of the decarbonization cycle (estimate, reduce and compensate) was the 20% of the score. This award was public, broadly informed to all suppliers; 28 suppliers postulated their initiatives in the environmental category; 3 of them were recognized: 2 big companies and one small supplier.

The decarbonization cycle has been written in contract clauses, incentivizing suppliers to estimate their emissions in Ecopetrol’s operations, defining decarbonization plans with goals for reducing their emissions and finally compensating through the purchase of carbon credits. These contract clauses recognize different levels of appropriation of climate change strategies in the broad types of markets and Ecopetrol’s suppliers.

At the end of 2022, 99 contracts included decarbonization clauses, represented 23% of total procurement spend and 18% of total GHG emissions inventory of the supply chain. The decarbonization clauses has been the vehicle to involved suppliers, through the developing of their baseline and decarbonization plan.

Supplier engagement in decarbonization strategy provoque that 103 suppliers informed their emissions reduction goal in Ecopetrol operations.

Ecopetrol adopted a circular economy model for the supply chain, optimizing and extending useful life of materials and minimizing waste generation.

a. Main outcomes

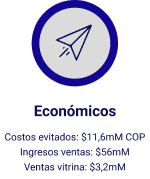

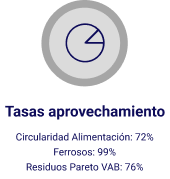

A quantity of 34.176.254 kg of waste were valued, representing income sales of $47,6mMCOP, and an increase of 5% in quantity compared to 2021. From the total amount of waste, 94% corresponds to ferreous scrap, that is 100% useful.

Also, due to circular models, $3,5mM of avoided costs were achieved for sales of waste.

Projects were developed to incorporate circular economy into supply Business models.

Beneficios

About 5.8 Ton of waste were used, corresponding to 76.5% of the total waste generated in the services of catering, maintenance and construction of non-industrial facilities, cleaning and cafeteria, and hoteling, due to initiatives like use of demolition and construction waste in landfills and embankments, ferrous, recycling, composting, among others.

The following video shows an example of useful life extent in catering service in Orinoquia region.

72% was achieved in the indicator of circularity in materials/inputs in catering service, increasing 3 points compared to 2021. This indicator improved thanks to circular actions regarding the entry of inputs related to purchases with green certification and green businesses; and at the same time, circular outings based on actions such as composting and vermiculture.

b. Awards

In September 2021, the United Nations Industrial Development Organization -UNIDO- recognized Ecopetrol as a leader company in the implementation of Chemical Leasing model, which is a service business model that shift from increasing sales volume of chemicals to a service pay approach that allows:

- Efficient use of chemical products

- Waste minimization

- Extent useful life of a chemical product

- Efficient resources use

a. Non-industrial facilities

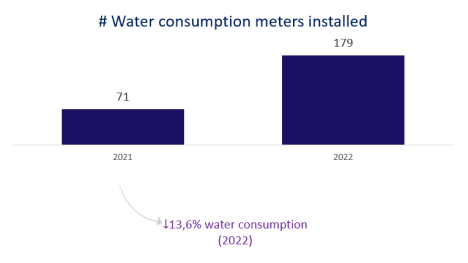

Ecopetrol has defined a 2030 goal of saving 20% of water consumption in non-industrial facilities prioritized, into the zero water discharges strategy. The process has been implemented in two stages:

1. Measurement: Water consumption meters are installed in non-industrial facilities to measure baseline and continuous monitoring of water consumption in each building. At the end of 2022, 179 non-industrial facilities had installed water consumption meters, continuously generating data.

2. Intervention: With the data of water consumption meters, Ecopetrol analyzes the main causes of consumption, depending on the type of building, and implements water savings strategies for each non-industrial facility. At the end of 2022, 71 non-industrial facilities reduced 13,6% water consumption compared to 2021 baseline.

a. Indirect water footprint

In the zero water discharges roadmap, Ecopetrol reports and achieved the certification of its direct water footprint in big four assets. Complementary, Ecopetrol is calculating its indirect water footprint, thanks to supplier engagement of some procurement categories:

- Contracts that have intensive use of raw materials as pipeline, cement, barite, and calcium carbonate.

- Waste management through bioremediation, landfill, incineration, and dump

54 suppliers are part of the prioritized categories in Ecopetrol’s indirect water footprint.

Within the framework of the Ecopetrol Group's 2040 TESG strategy, Biodiversity has been defined as an outstanding element. Likewise, Nature-Based Solutions (NbS) have been identified as an efficient alternative to maintain Biodiversity and Ecosystem Services in strategic areas, as well as improve the livelihoods of local communities.

In this context and as the first topic to include in supply chain model, Ecopetrol looks to engage suppliers of logistics, construction, maintenance, office supplies and packaging to achieve Net Zero Deforestation in indirect operations, thanks to three types of actions:

- Sustainability criteria for the selection and evaluation of suppliers

- Training and collaboration with suppliers around natural capital

- Transparency and communication towards Net Positive Impact on Nature and Net Zero Deforestation in the supply chain.