PautaInternas

PautaInternas

buscador

buscador

Economics and governance

Economics and governance

Economics and governance

Jun 1, 2023

Ecopetrol requires its suppliers and workers with a current or potential commercial relationship to strictly comply with ethical principles and regulations on the prevention of conflicts of interest and ethics, fraud, corruption, bribery, money laundering, financing of terrorism and restrictive practices free competition. It is important to mention that all Ecopetrol’ s suppliers must declare to know and comply with the obligations of ethics, transparency, and compliance in contracting, which are an essential part of the contract and includes, among others, the following regulations, and policies: Code of Good Governance, Code of Ethics and Conduct, anti-bribery laws, accounting standards and implementation of internal control mechanisms.

The Supply Chain Management seeks to guarantee the ethical, transparency and integrity of the Process, by the compliance of the guidelines stated on the Corporate Model, the risks´ identification and mitigation and the generation of share value for all chain actors. For which, it has developed a Control, Assessment and Development System, composite of:

Listado Económico Tarjetas En

Listado Económico Tarjetas En

Listado Económico En

Listado Económico En

Legality and Transparency Pact

In 2021, Ecopetrol signed the Legality and Transparency Pact with Chambers of Commerce, which seeks to promote the local contracting under a framework of law compliance and free and fair competition principles.

2023 Pact Endorsement:

-

Continue impacting the regions’ economic growth, within the sustainable development principle.

-

Include the energy transition framework according to Ecopetrol´ s 2040 Strategy "Energía que transforma”.

-

Inclusion of Ecopetrol’ s Business Group 🡪

Risk Analysis

1. RISK IDENTIFICATION

Ecopetrol’ s Ethics and Compliance Area developed the risk identification in operations, businesses, or contracts methodology, which defines and analyzes each of the possible risk factors in a business relation. According to its definition and guidelines the Supply Chain Process will implement the required measures and actions defined by the Compliance Area for the treatment of the different risk factors:

COUNTERPART:

COUNTERPART:

Natural or legal person, national or foreign with whom it is sought to establish or currently holds a commercial relation

PRODUCTS:

PRODUCTS:

Goods and services offered by the supplier in the development of its corporate purpose.

DISTRIBUTION CHANNELS:

DISTRIBUTION CHANNELS:

Means used by the supplier to offer and market its goods and services.

TERRITORIAL JURISDICTION:

TERRITORIAL JURISDICTION:

Risk rating of the geographic areas of the supplier origin, this factor´s risk management is characterized by the level of risk assigned:

Restricted: The supplier will be immediately blocked at Ecopetrol’ s Supplier System Information.

Restricted: The supplier will be immediately blocked at Ecopetrol’ s Supplier System Information.

Medium or High: the supplier is asked for its policies, programs or ethical guidelines and internal control system, this evidence is analyzed by the Compliance Area and the Supply Chain Process executes the actions defined for the supplier´s treatment.

Medium or High: the supplier is asked for its policies, programs or ethical guidelines and internal control system, this evidence is analyzed by the Compliance Area and the Supply Chain Process executes the actions defined for the supplier´s treatment.

Low: It does not present a risk for the operation.

Low: It does not present a risk for the operation.

2. SECTOR´S RISK AND OPPORTUNITY ANALYSIS

The Supply Chain Process designed the Market Indicators Surveillance System, through which 50 national and international indexes are monthly analyzed to measure and monitor inflation and key variables that directly or indirectly impact the goods and services rates required by Ecopetrol and its Business Group.

Additionally, global risks are monitored in Economic and Geopolitical, Environmental, Social and Technological aspects, covering each of the dimensions defined for sustainable Supply Chain Management (T-EGS®).

3. IDENTIFICATION AND MONITORING OF COMMODITIES, GOODS AND SERVICES REQUIRED

Committed to supporting the energy transition, the Supply Chain Process, through the monitoring of 10 key indicators, developed a historical price evolution monitoring board for the different goods and services required for the operation and, also, for the essential needs of the Energy Transition Strategy.

Currently, the Process is working on the deployment of a prospective analysis concerning the impacts of decarbonization, climate change, reduction of working hours and taxes, to count with risk anticipation mechanisms, containment measures and take advantage of market opportunities. As well, the Supply Chain seeks to generate the respective monetization of these variables impact on Ecopetrol’ s profit and loss statement (P&L).

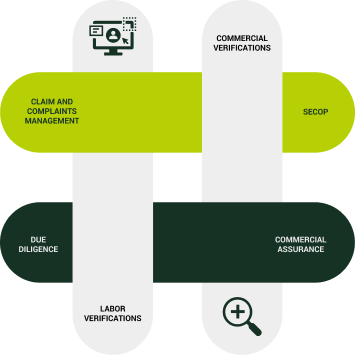

Process Execution Verification

To guarantee the correct execution of the contractual relations, Ecopetrol has generated an Integral Ecosystem of Risk Management Measures and Contracts Execution Verification Mechanisms:

COMMERCIAL VERIFICATIONS

COMMERCIAL VERIFICATIONS

Validations are carried out to verify the compliance level of commercial obligations in local contracting by critical contractors. With these reviews Ecopetrol generates alerts and recommendations to the suppliers for its respective management and resolution. These verifications were strengthened in 2022 through one of the most strategic project of the Company, assessing 6 critical contracts in Puerto Wilches municipality.

SECOP

SECOP

Report and disclosure of the contracting managed by Ecopetrol in the National Electronic System of Public Contracting.

COMMERCIAL ASSURANCE

COMMERCIAL ASSURANCE

Includes:

- Internal Early Warning System.

- Internal Risk Management System

- Precritical and Critical Contracts Analysis

LABOR VERIFICATIONS

LABOR VERIFICATIONS

Visits are made to suppliers to ensure compliance with labor obligations and identify breaches, occupational risks and early alarms that may impact labor normality. These verifications are recorded in a standard report that allows the same findings parameters and the identification of improvement actions. In 2022, 390 verifications were carried out.

DUE DILIGENCE

DUE DILIGENCE

62 internal due diligence of suppliers and contractors were carried out in 2022 to identify and prevent violations of the Code of Ethics and Conduct related to corruption, bribery, fraud, money laundering, terrorism financing, conflicts of interest, ethics conflicts and unfair competition acts.

CLAIM AND COMPLAINTS MANAGEMENT

CLAIM AND COMPLAINTS MANAGEMENT

Ensure the implementation, by the Ecopetrol´ s suppliers, of strong, efficient and timely systems for Petitions, Complaints and Claims the Management and its respective disclosure to stakeholders.

Process Assessment

Supply Chain Process Internal Audits:

Supply Chain Process Internal Audits:

In 2022, Ecopetrol carried out internal audits to:

Evaluate the management of critical suppliers that provide technology and information services, as well as the compliance of the guidelines defined at the corporate level for relations with third parties.

Evaluate the management of critical suppliers that provide technology and information services, as well as the compliance of the guidelines defined at the corporate level for relations with third parties.

Review the implementation level of practices and strategies defined for the Master data management.

Review the implementation level of practices and strategies defined for the Master data management.

Verify the implementation and operation of cybersecurity and cyber defense initiatives.

Verify the implementation and operation of cybersecurity and cyber defense initiatives.

Assess the assurance of personal data treatment in compliance with Law 1581 of 2012

Assess the assurance of personal data treatment in compliance with Law 1581 of 2012

Measure the CAPEX execution capacity to ensure the achievement of investment goals.

Measure the CAPEX execution capacity to ensure the achievement of investment goals.

Assessments carried out by an independent accredited auditing body

Assessments carried out by an independent accredited auditing body

Certain goods and services needed by Ecopetrol require an external evaluation and certification to be invited, verified, and establish a commercial relation. Therefore, they must carry out the assessment through a third party and present it to Ecopetrol in a current state and guarantee its update, otherwise the supplier will not be able to participate in the selection methods.

The type of certification the supplier must have, is determined according to its economic activity. These accreditations are detailed below:

Compliance with national and international standards and Supply Chain Management Best Practices

Compliance with national and international standards and Supply Chain Management Best Practices

Ecopetrol’ s Supply Chain is a national and international benchmark due to its remarkable management, therefore, it continually challenges its performance to incorporate the best market practices and accomplish national and international standards, both in its operation and in its suppliers’ performance. The decisions and strategies made for the Process Evolution have taken into account the recommendations and assessments carried out by international consultants, such as Boston Consulting Group, Kearney and Mckinsey, which have allowed the identification of the Process´ maturity level, including suppliers´ management.

According to these assessments, Ecopetrol have been recognized with a high level of performance, being classified within the top quartile of the industry in the "Aspirant" category in the Kearney Assessment of Excellence in Procurement (AEP) measurement and the consultancy for strengthening of suppliers and contracts segmentation carried out by Boston Consulting Group, which have been implemented in the different phases of the supply chain process.

Internal Health, Safety, Environment, Quality (HSEQ) Audits

Internal Health, Safety, Environment, Quality (HSEQ) Audits

Ecopetrol has an internal HSEQ audit system, which seeks to:

Determine the conformity of HSEQ management systems.

Assure the capacity of the HSEQ management systems to ensure the compliance of legal, regulatory, and contractual requirements applicable.

Assure the capacity of the HSEQ management systems to ensure the compliance of legal, regulatory, and contractual requirements applicable.

Analyze the effectiveness of HSEQ management systems in ensuring that the organization meets specified objectives.

Analyze the effectiveness of HSEQ management systems in ensuring that the organization meets specified objectives.

Identify aspects of potential improvement in HSEQ management systems.

Supplier Analysis

SUPPLIER VERIFICATION AND QUALIFICATION

SUPPLIER VERIFICATION AND QUALIFICATION

The supplier verification process evaluates the suppliers ´minimum requirements fulfillment for the company’s approval in Ecopetrol’ s Suppliers Information System. The requirements that suppliers must meet are determined by the following variables:

If the supplier does not comply with the established requirements or do not ensure its qualification in the Information System, the supplier will not be “Approved”, therefore, it cannot be invited to participate in Selection Methods or be contracted by Ecopetrol.

Consult the specific verification requirements for each supplier type:

Detailed suppliers' verification requirements

SUPPLIER FINANCIAL CAPACITY ANALYSIS

SUPPLIER FINANCIAL CAPACITY ANALYSIS

Evaluates the financial capacity and risk of potential suppliers to prevent possible breaches of their contractual obligations, through a comprehensive historical analysis of the suppliers’ financial information (3 years).

This analysis provides a supplier financial profile, which contemplates the ability to finance working capital requirements, with internal sources derived from the contracts in progress and/or potential new contracts, as well as its financial profitability, debt, and liquidity.

The assessment ponders the following aspects:

The companies that are identified with "Very High" and "High" risk, must be managed through the identification, design, and implementation of controls and mitigants so that suppliers remain at residual risk levels that do not compromise the agreed contractual obligations.

TESG® FACTORS INTO SUPPLIER SELECTION

TESG® FACTORS INTO SUPPLIER SELECTION

During the Supplier´s registration, selection, and assessment performance processes, Ecopetrol considers the following sustainability (T-ESG®) factors:

Suppliers must be registered at Ecopetrol´s Supplier System Information (SIPROE), meeting different requirements such as: management systems certifications, HSE and technical certifications, among others according to their procurement category (economic activity).

Aplication:

Weight: 100%

National Government Legislation (Law 816 of 2003) aims to support the national industry through public procurement. During the selection process this is a mandatory evaluation factor.

Aplication:

Weight: 10%

-

Promotes suppliers´ local contracting.

-

Fosters the implementation of value generation activities in the territories of operation.

Aplication:

Weight: Optional factor - its weight is determined in each procurement strategy..

It establishes parameters in environmental aspects (decarbonization, waste, water, biodiversity, among others) that will be evaluated to the suppliers during the selection methods and their actual compliance during contracts´ executions.

Aplication:

Weight: Optional factor - its weight is determined in each procurement strategy.

Promotes local hiring of people classified into one or more of the following groups: women, people with disabilities, first job, ethnic groups, and victims of armed conflict.

Aplication:

Weight: Optional factor - its weight is determined in each procurement strategy.

Suppliers are evaluated by 5 indicators: 1. Operating efficiency, 2. Accomplishment of Deadlines, 3. Administrative Aspects, 4. HSE and 5. Environment Management.

Aplication:

Weight: Each factor has an individual weight of 100% .

Required for new suppliers.

Required for new suppliers.

Required for existing suppliers.

Required for existing suppliers.

PERFORMANCE ASSESSMENT

PERFORMANCE ASSESSMENT

Establishes the methodology and criteria to assess the effectiveness and efficiency of suppliers´ performance to ensure the fulfillment contracting obligations and assure contractual relations with the best suppliers of goods and services. The performance assessment is a permanent process carried out through the analysis of suppliers´ obligations accomplishment during the contractual relations according with the formalized indicators for each contract.

This assessment is carried out through the measurement of 5 standard criteria:

In this process, Ecopetrol provides a guideline on the assessments that must be carried out throughout the contractual relationship, considering variables such as frequency, applicable criteria, among others, according to the specific needs identified during the supply planning and that are correctly formalized in the signed contract.

Additionally, the performance assessments also indicates that for contracts whose performance term exceeds six (6) months and are classified as Medium (M), High (H) or Very High (VH) HSE Risk, it is mandatory to complement the Performance Assessment with at least one annual audit in the place where the contract is performed, preferably to be carried out within the first three (3) months of the contract performance.

As a due diligence mechanism, for the planning, invitation, and contract subscription during the selection process, Ecopetrol review and considers the favorable and unfavorable information about supplier´s performance such as results, trends, contract´s category and any other data that may be relevant.

Supplier Development

Corrective action plans for suppliers

Corrective action plans for suppliers

In accordance with the results of Supplier´s Performance Assessments, Ecopetrol and the supplier may agree to generate an improvement plan that allows managing and closing the gaps identified during the contract execution. The development of the improvement plan must consider the level of deviation in the qualification of the evaluated criteria and the contract execution term. For its application the suppliers must prepare a proposal of the foreseen improvement plan, and it must be approved by Ecopetrol before beginning its implementation.

Corrective action plans are only applied to significant suppliers identified through the supplier segmentation which is carried out by Ecopetrol on an annual basis.

With the approval of the improvement plan, the supplier agrees to fully adopt and comply with the agreed actions, and Ecopetrol´ s contract monitoring officer must review and ensure the quality of the deliverables and the timely closure of the settled activities.

- The Ecopetrol contract monitoring officer must review and ensure the quality of the deliverables and the timely closure of the settled activities. If it is identified that the actions agreed have not been implemented, the improvement plan must be suspended and invalidated. The officer must inform this situation to the supply category leader, the auditor, the technical and functional area (labor, environmental, commercial, HSE, among others) for the respective analysis and decision-making.

- The Supplier Performance Leader will monitor the coverage and effectiveness of the corrective plans implemented to guarantee the assessment and development of suppliers.

- The follow-up of the improvement plan is carried out under the framework of the performance assessment, however, to guarantee the effectiveness of the corrective plan, Ecopetrol monitors the supplier's performance during the year following its completion.

In 2022, 34 significant suppliers required the development and implementation of improvement plans due to the results of their performance assessments. Therefore, Ecopetrol, in mutual agreement with these suppliers, approved the generation of the respective plans, covering 100% of the suppliers which required corrective action plans to close the identified gaps.

In 2022, 100% of the suppliers with current corrective action plans presented an improvement in their performance.

Capacity building programs

Capacity building programs

Ecopetrol counts with different programs for suppliers´ capacity building, during 2022, 109 significant suppliers participated in one or more of the development actions, achieving a coverage of 91% of significant suppliers.

The Performance Review Meetings (PRM) is a relationship mechanism based on high-level meetings between Ecopetrol and its suppliers to enhance the value generation during the commercial relation through collaborative schemes. These sessions are implemented with the significant suppliers identified through the segmentation and aimed to capture mixed efficiencies activities along the contract performance.

The PRM counts with a broadly review about performance, results obtained, improvement opportunities and potential joints for value generation initiatives, among other critical success factors. This analysis is based on a strategic vision of the significant suppliers, and not on the execution of a specific contract, accordingly, in these meetings, issues associated to tariffs negotiation, administrative and transactional aspects or portfolios of supplier´s goods and services are not reviewed.

Through the deployment of these sessions, Ecopetrol seeks:

Strengthening of supplier compliance and ethical conduct and policies

The conduct of suppliers and their workers with whom Ecopetrol has a commercial relationship must be characterized by transparency, clear rules, and consistency; with a total rejection and zero tolerance of any conduct that goes against the postulates defined and adopted in the Code of Ethics and Conduct of the Ecopetrol Group. Therefore, training spaces have been developed to strengthen the knowledge and appropriation by suppliers of these standards, such as:

Improvement of business skills, diversity and inclusion policies and new technologies adoption

Ecopetrol has generated a portfolio of activities focused on ensuring suppliers´ development in critical topics such as Corporate and Supply Strategy, business capacities improvement, diversity and inclusion policies promotion and new market technological enablers integration, among others. The assurance of knowledge and management capacity of these aspects and the corresponding gaps identification and main levers for improvement are crucial objectives of each program deployed.

These actions have a great impact on suppliers´ development, since they are focused on the main needs found:

BUSINESS STRENGTHENING WORKSHOPS: Strengthen the business capabilities of suppliers, joint co-creation and contribute to closing identified corporate gaps identified.

T-ESG® CONGRESS: Increase suppliers´ capacities and commitment to sustainability (T-ESG®) management in their operations and improve technical and administrative skills of diverse productive entrepreneurs.

DIVERSITY AND INCLUSION POLICIES: Promote the inclusion of diversity and inclusion policies by suppliers.

DIFFUSION WORKSHOPS: Disseminate information of interest to suppliers on ethical, HSE, corporate issues and the modifications described in the Contracting Manual, among others.

ARIBA TRAININGS: Program to train suppliers about the supply chain technological platform transition.

Due to Ecopetrol's role in the national economy, the company identified the municipalities where its impact have a major impact, analysis based on its importance in the regional development, evaluating its participation in job creation, taxes, royalties, aspects that promote and generate dependence on the oil & gas industry.

Under this scenario, the company seeks to diversify the regions by supporting the incursion into new businesses and the enhancement of regional productive matrix, supporting the suppliers´ formalization, financial management reinforce, marketing and other critical business aspects improvement.

One of the initiatives deployed by Ecopetrol for the suppliers´ development was the establishment of 2 business schools:

To promote the safe, healthy, and environmentally responsible performance of a supplier and ensure compliance with applicable HSE legislation and regulations, Ecopetrol implemented an Internal System to share and implement good HSE management practices by suppliers. For the development of this scheme, Ecopetrol prioritized 36 HSE practices on topics such as: Safety, clean, and healthy work promotion; Process safety; HSE management systems; Risk and hazard management; Incident Investigation, Waste Management, Work Control, Change Management, Operational Discipline and Process Technology, among others.

Once the good practice is shared by Ecopetrol, the supplier must complete the suggested actions within a maximum period of 1 month and the HSE area will oversee monitoring compliance with the proposed activities.

Additionally, to ensure the reliability of the HSE management model and results of suppliers´ performance assessment, Ecopetrol developed the HSE findings report module for suppliers on Salesforce technological platform, which allows the record of the HSE findings identified during the contract performance with online information access to carry out an objective, coherent and timely measurement of the HSE performance criteria and support HSE management decision-making, by the different interlocutors of the supply chain management process.

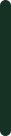

Regional Economic Impact Model

Looking to increase Country´s sustainable territorial development, the Supply Chain Management created the Regional Impact Model of Ecopetrol’ s Operations which considers six dimensions:

The implementation of this Model allows:

-

Quantify Ecopetrol’ s economic and social contribution in the territories of operation.

-

Locate future projects in municipalities with potential to reinforce sustainable local development.

-

Carry out simulations of production fluctuations or new clean energy businesses in local economies.

-

Identify a new view of Ecopetrol’ s social and economic benefits and support the information delivered to National Authorities around this.

Likewise, this model´s simulator can estimate the potential effects of production rise on territories in terms of education, health, public services and security, diagnosis supported by the Municipal Performance Measurement-MDM of the National Planning Department.

World-class Talent

Internal training program for Supply Officials

Supply Management recognizes the training, reskilling and installation of new capacities and abilities of the human talent to reach and maintain the competence level to face the challenges imposed by new T-ESG® trends, climate change and energy transition for which it has designed a training system for officials.

The internal training program consist of:

Los Andes University: Strategic Supply Chain Program: Count with qualified human talent for processes´ transformation, through training in the necessary capacities, skills and knowledge of supply chain and its sustainable management, ensuring that supply chain officials have the fundamental skills in relevant aspects such as strategic thinking, leadership, financial evaluation, risk management and decision making, among others. This Program is developed in alliance with Los Andes University.

Los Andes University: Strategic Supply Chain Program: Count with qualified human talent for processes´ transformation, through training in the necessary capacities, skills and knowledge of supply chain and its sustainable management, ensuring that supply chain officials have the fundamental skills in relevant aspects such as strategic thinking, leadership, financial evaluation, risk management and decision making, among others. This Program is developed in alliance with Los Andes University.

Massachusetts Institute of technology (MIT): Digital transformation: Massachusetts Institute of Technology (MIT) Training Program for supply chain officials on leadership of digital transformation skills.

Massachusetts Institute of technology (MIT): Digital transformation: Massachusetts Institute of Technology (MIT) Training Program for supply chain officials on leadership of digital transformation skills.

Javeriana University: Analytics and data science: Training for the development of analytical solutions. Program developed in alliance with Microsoft and the Javeriana University.

Javeriana University: Analytics and data science: Training for the development of analytical solutions. Program developed in alliance with Microsoft and the Javeriana University.

Contract Monitoring Officials Academy

Contract Monitoring Officials Academy

Contract monitoring officers are key interlocutors for the correct performance of the agreed contractual obligations; therefore, the Supply Chain Process recognizes the importance of updating and strengthening their knowledge by designing training programs on high relevance topics for its function. During 2022, different workshops and forums were held covering topics such as the public works contribution, human rights, suppliers’ verification, payment management, assurance of labor and commercial obligations, HSE management and due diligence, among others.

Additionally, contract monitoring officers received the International Association for Commercial and Contract Management (IACCM) Certificate.

Environmental Management Training

Environmental Management Training

In 2022, Ecopetrol began an environmental management internal training plan through the development of sessions regarding the decarbonization strategy (compensation, green clauses and decarbonization plans) with the attendance of 315 attendees during the different activities carried out.

In order to have a greater knowledge apprehension and commitment with environmental objectives, the supply chain management deployed the definition of roles and responsibilities for the main actors in this criteria including into their individual performance objectives, the targets to be met in terms of environmental management, likewise, to guarantee the information accessibility, the process counts with a digital repository for internal training with the resources and relevant material for a correct environmental management.

HISTORICAL FINANCIAL INFORMATION

HISTORICAL FINANCIAL INFORMATION FINANCIAL PROJECTION

FINANCIAL PROJECTION SENSITIVITY SCENARIOS

SENSITIVITY SCENARIOS PERFORMANCE IN CURRENT AND HISTORICAL CONTRACTS

PERFORMANCE IN CURRENT AND HISTORICAL CONTRACTS ECOPETROL´S PAYMENT CYCLES

ECOPETROL´S PAYMENT CYCLES OPERATING EFFICIENCY

OPERATING EFFICIENCY OPERATING EFFICIENCY

OPERATING EFFICIENCY ADMINISTRATIVE ASPECTS

ADMINISTRATIVE ASPECTS HSE MANAGEMENT

HSE MANAGEMENT ENVIRONMENT MANAGEMENT

ENVIRONMENT MANAGEMENT

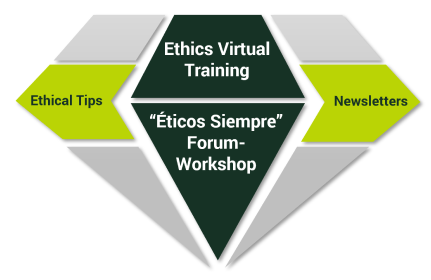

Ethical tips

Ethical tips Newsletters

Newsletters Ethics Virtual Training

Ethics Virtual Training "Éticos Siempre" Forum-Workshop

"Éticos Siempre" Forum-Workshop